No.98 The Peco Streamline 3 Way Point.

The Peco Streamline 3 Way point is an extremely useful space saving device. This Post is prompted because I had to sort out a couple of problems with the installation of my own three way point. I was also aware that other modellers were finding difficulties with the operation and installation of their 3 way points.

The design of the point is symmetrical and has the

appearance of a LH point being placed directly on top of a RH point. As a

consequence the construction of the point is quite complex and the point

requires careful handling especially during installation. When first marketed

by Peco the point was only available with ‘Insulfrog’.

The view below shows my

first ‘Insulfrog’ point but reinstalled on my second layout.

Peco Code 100 3 Way Insulfrog Point – the Park View

Layout 1990s

The big advantage of the ‘Insulfrog’ point is that it does

not require any separate electrical switching and hence is suitable for manual

or simple mechanical operation. My same point was reused again on the current

layout. However I would say that a big disadvantage of the ‘Insulfrog’ point is

that with three dead plastic frogs some locomotives, notably six coupled

varieties with no electrical pickups on the tender or carrying wheels will

always stall when using the point. I decided to replace the point with the

‘Electrofrog’ version.

Peco Code 100 3 Way Electrofrog Point – box

Peco Code 100 3 Way Electrofrog Point – in situ

The ‘Electrofrog’ point is more complicated than its

‘Insulfrog’ cousin and cannot be used straight from the box. In order to

maintain the correct polarity of the live frogs additional external electrical

switches are required. The 3 way point is fitted with the necessary electrical

leads but it is left to the purchaser to supply the necessary switches.

Peco Installation Instructions

Peco have designed the 3 way point around their own

products. Changing the polarity of the live frogs requires the use of two

single pole double throw (SPDT) switches operated at the same time as the point

blades are being changed. Peco recommend that the Electrofrog point is operated

by two of Peco’s own PL-10 Turnout Motors together with two PL-13 Accessory

Switches which are made to clip onto the underside of the Peco Turnout Motor.

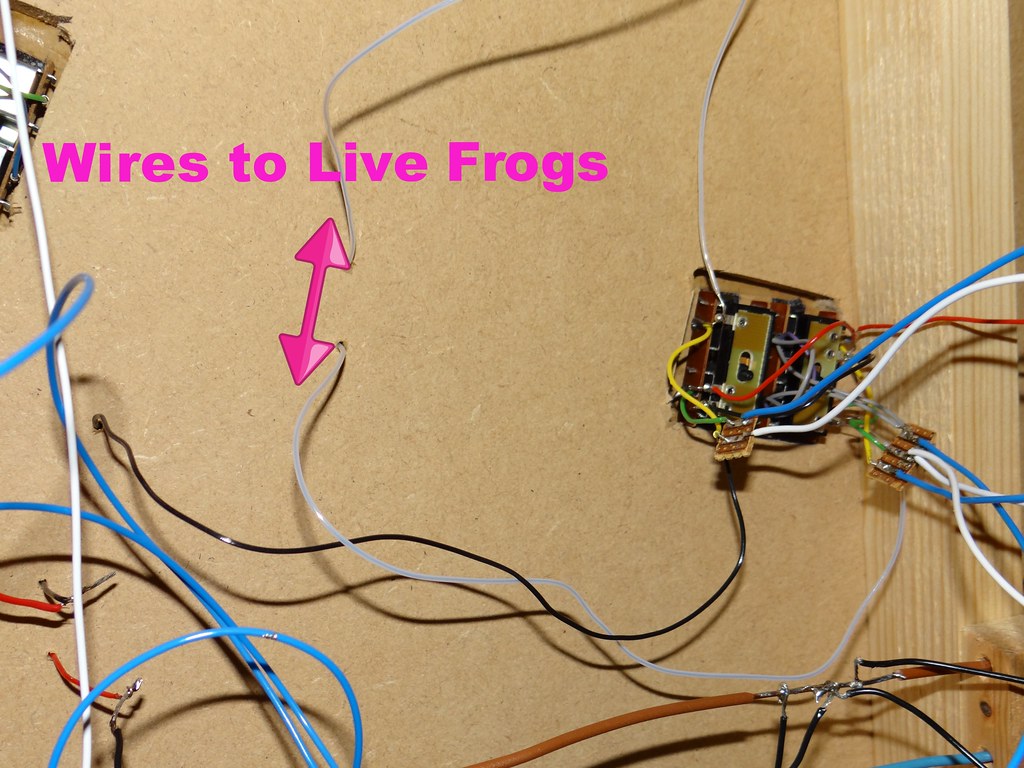

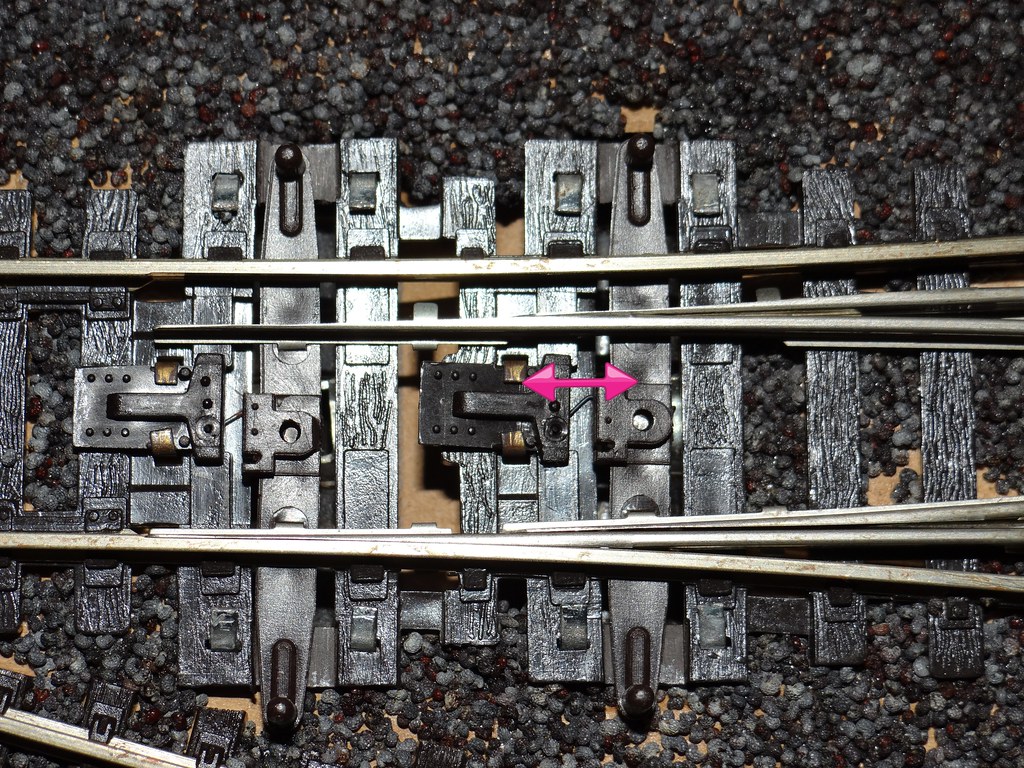

3 Way Electrofrog installation from below

First a general view of my installation from below showing

the sleeved leads provided by Peco dropping down from the live frogs and

attached to the two clip on PL-13 Accessory Switches beneath the Peco PL-10

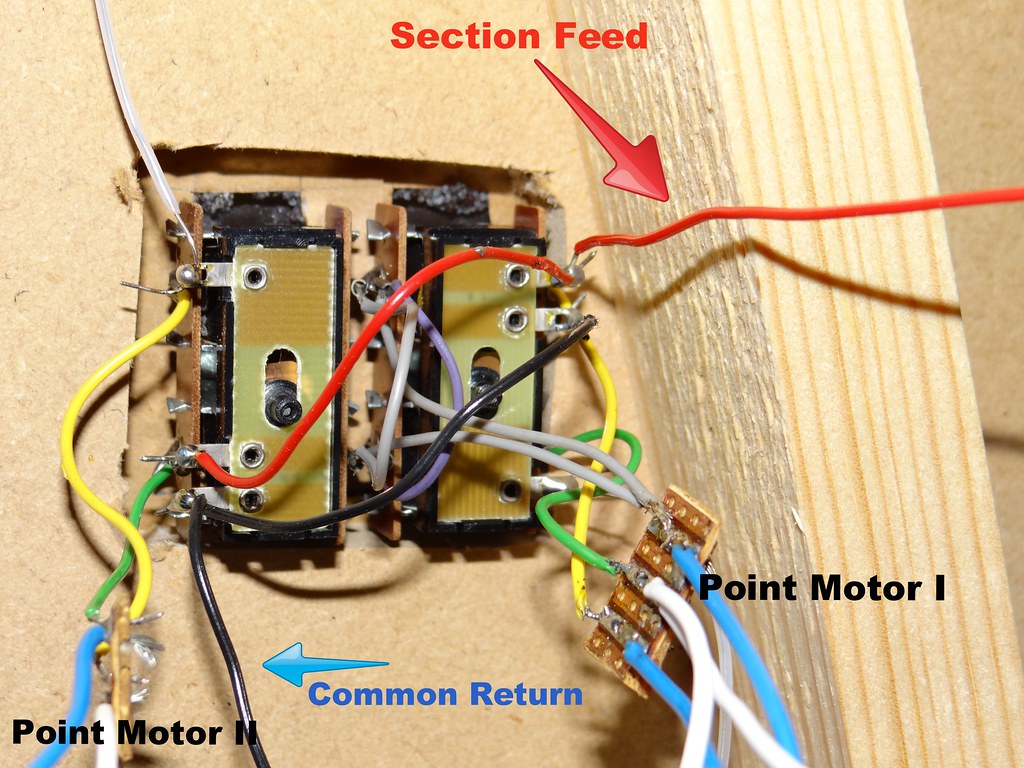

Turnout Motors. The second view here below is a more detailed image showing the

two point motors with accessory switches. I have attempted to colour code the

wiring both to assist with installation and then tracing of any subsequent

faults. The track feeds are the red and black wires. The yellow, green and grey

wires are the connections to the point motors.

Detailed view of wiring to Accessory Switches and Point

Motors

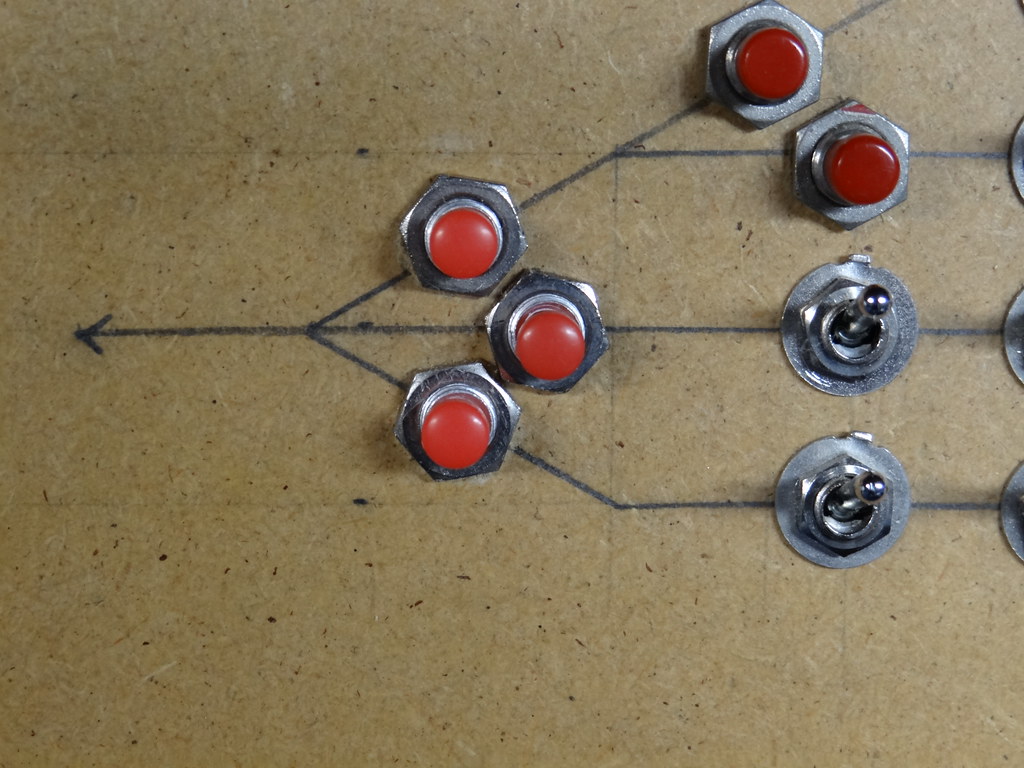

Operation of my installation is by three momentary contact

push button switches.

Top side of control panel

Whilst the individual switches are very cheap, they are

obviously not quality products and their operational life seems to be very

variable.

Push button switch

When first fitted my 3 way Electrofrog point worked nearly

very well. However after ballasting I began to experience problems where the

tracks at the frog end of the ceased to be isolated. Coupled with this

behaviour was the realisation that locomotives were derailing because the point

blades were not tight up against the relevant stock rail.

Some of this behaviour was probably self inflicted. When I

replaced the ‘Insulfrog’ point with the ‘Electrofrog’ version, to save time I

dropped out the old motors (from the 1980s) without disturbing any wiring and

then refitted them (from underneath) to the replacement point. Peco recommend

that the motors and switches are all fitted and tested prior to track laying. I

didn’t and whilst the Peco turn out motors are good they must be perfectly

aligned to give a good clean throw of the points. Add in the extra load from

the accessory switch and it becomes rather obvious why my point blades (and the

underlying switches) were not fully opening and closing. Paste and surplus

ballast around the point blades must have been the last straw in terms of

friction and the load to be overcome by the point motor.

It should also be noted that I do not use a Capacitor

Discharge Unit (CDU). With my single push buttons, selecting the middle road,

uses one button to energise both the point motors. It was becoming noticeable

that this switch for the middle road was not functioning – obviously the high

current to energise two motors with attendant switches was proving to be all

too much and the switch contacts were burning out?

In the short term I have renewed all three push buttons. I

have checked and re-soldered all the connections. Above ground so to speak I

weakened the operation of the ‘over centre’ spring at the toe of the point.

This can be achieved by pushing the spring cover back and increasing the

separation from the tie bar. Finally to guarantee trouble free operation I

always select the ‘middle road’ prior to setting either the Left or Right hand

tracks.

Close up of ‘over centre’ springs

Comments