No.103 Have I missed the point – CDUs with Peco solenoids

I recently added my two-pennies-worth to an RMweb question about motorising Peco points. As a consequence and after some thirty years of playing with model trains I have now installed a couple of Capacitor Discharge Units (CDUs). What do I think? Well I have mixed feelings.

First some pictures (scanned images) going back in time to

earlier layouts.

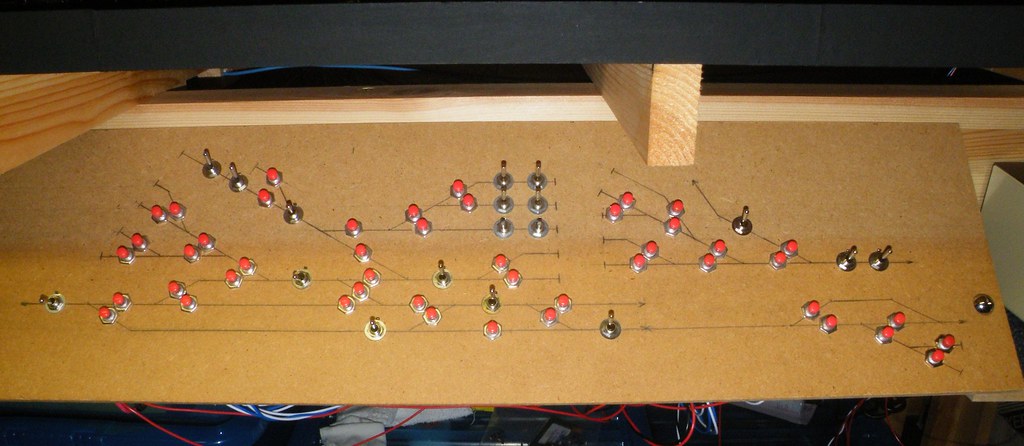

Control panels with push buttons Bracken Ridge

This was the Bracken Ridge layout from the early 1980s. I

cannot remember but I don’t think model railways had heard of CDUs in the early

80s. Certainly I didn’t use a CDU and the Peco solenoids attached to my points

were operated by momentary contact switches wired in parallel directly from the

16v auxiliary AC supply from my Hammant and Morgan controllers.

Control panel Park View NB Hi-tech wire connectors to

controller

By the 1990s we had moved house and all the track, point

motors and switches were reused in the new Park View layout. Again it never

occurred to me nor did I find it necessary to use a CDU. The point motors, up

to two at a time, were operated directly from the 16v auxiliary AC supply.

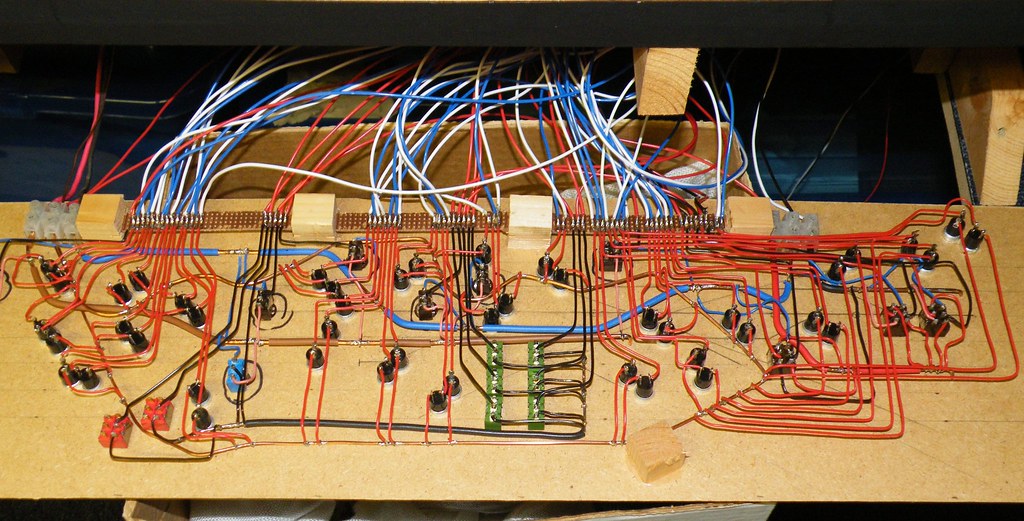

Current panel, front

Current panel, rear

Move forward to 2007 and the start of construction of the

current layout. The same momentary contact switches were reused along with the

original Peco point motors. All the old small radius points were replaced by

new large radius points but the original solenoids were retained. The system

has been expanded, but this has been done by adding to the original rather than

by replacement. As a result the current control panels contain a selection of

the original momentary contact switches from the late 1970s. Yes some point

motors buzz but the points all operated.

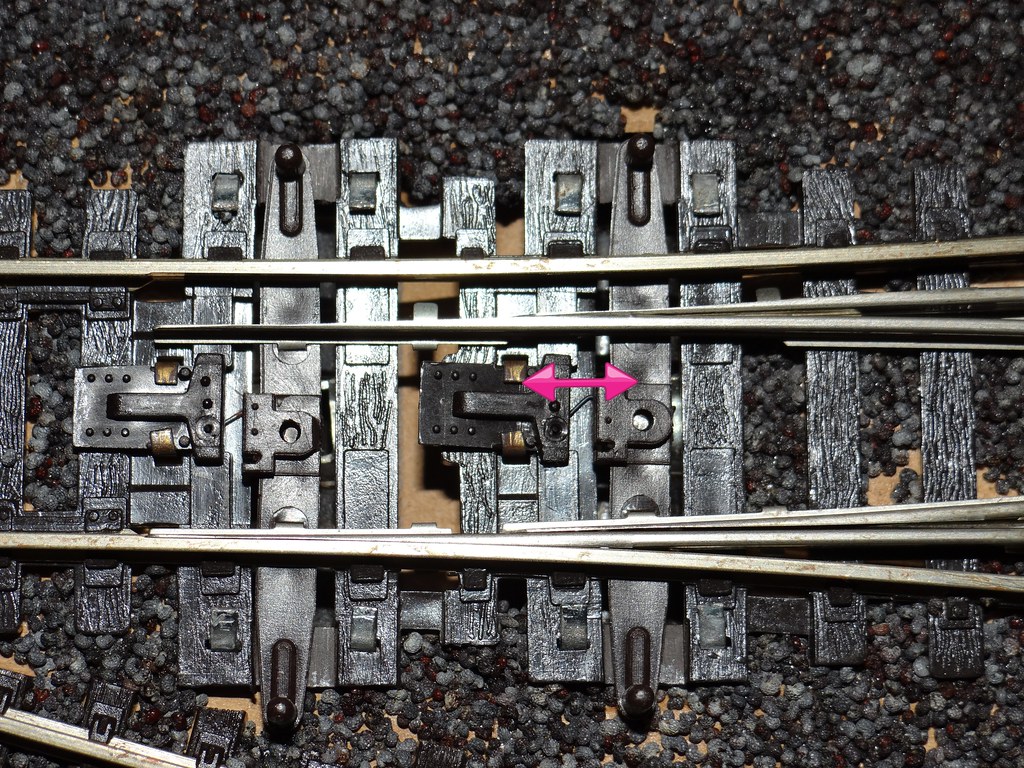

Have there been any problems? Well yes, operation of the

Peco 3-way point has been an issue. The 3-way point on the two early layouts

was the Insulfrog version which simply required two solenoid motors. The

current 3-way points are both Electrofrog which require two solenoids each

fitted with a Peco changeover switch. I sense that the operation is at the

limit of my system. I have had to replace two or three momentary contact

switches, which I am guessing have ’burnt out’ due to the high current required

to operate the two rather heavily loaded solenoids all at the same time. I was

told by ‘kevinlms’ (RMweb)

“.....that is due to switching a largish

current off, when you release them. That is another advantage of using a CDU,

as the intention is to release the switch AFTER most of the power has

discharged and there won't be any arcing.”

CDU with single 40v2200 µf capacitor

In the past I had purchased a small CDU on EBay. I inserted

it into the AC supply to my point motors. I was not impressed. Some points

would operate – most would not. As with a lot of things off eBay you need to do

some homework before bidding. Obviously I had not done enough research. I would

continue operating my points without CDU and would hope to resell the eBay

purchase at a later date.

Over the years I have built up a collection of over 100 Peco

points all fitted with Peco solenoids. During thirty years of operation I have

never had to replace a single Peco solenoid. Over the same period I have had to

replace maybe five or six momentary contact switches. Some of these were

damaged during the process of soldering the connections.

CDU with 2x 40v2200 µf capacitors

Following the suggestion here on RMweb that I was risking my

switches due to arcing I have now installed a couple of Gaugemaster CDUs (one

at the controller at each end of the layout). Initially the resulting operation

of my points was disappointing. Some worked brilliantly with a quick snapping

action. Others simply twitched and could not be persuaded to operate. Prior to

inserting the CDUs all points would operate. In order to persuade all my points

to continue operating with the CDU I had to replace a couple of I would say my

older momentary contact switches.

Mini round momentary push to make switch – UK sourced –

maximum current 1amp

The technical advice from Peco

for their PL10 point motor states as follows; “A Capacitor Discharge Unit can

be used but is not necessary.” If you go to the instructions for your Gaugemaster Controller (D, DS and P), then the

advice is to use a Capacitor Discharge Unit. So – some confusion?

A search of the Internet is equally unhelpful but does

provide some useful pointers. Firstly it is not all about electronics. I have

read that the internal friction within the solenoid motor can vary

significantly both due to manufacture and installation. (How many of us have

reattached a Peco point motor the other way round to get it to work?). Secondly

what about the resistance of the over-centre spring at the toe of the point?

Mass producing identical springs can be a problem and Peco provide a sliding

mechanism for the very purpose of adjusting this resistance. I have changed the

spring tension on numerous of my points to assist operation.

The slider for altering spring tension

Then as mentioned above there might the addition of a Peco

Accessory switch which will further add to the mechanical load.

My knowledge of things electrical is rather basic but there

seems to be a consensus on the Internet that the theoretical power needed to

operate one point solenoid motor is a little under 1 amp. Given the range of

mechanical resistance described above that might have to be overcome it could

be necessary to have anything up to 3 amps available to power each solenoid. If

there are 2 or more points to be operated simultaneously then the minimum

current requirement rises close to 2 amps. It follows that if the maximum

output from a controller or transformer is only 1amp (which seems to be fairly

typical) then there are going to be occasions when this will be insufficient to

operate a particular point, or set of points.

Rear of Gaugemaster Controller (Model P) showing

accessory sockets and rated power output

On the electrical side maintaining voltage at the point

motor is critical. Long distances between point motor and the controller or

transformer will add resistance to the circuit leading to a drop in voltage and

a corresponding lack of energy at the point motor. To minimise voltage drop I

use 16/0.2 wire (16 core each of 0.2mm2) for most of my connections.

Some people prefer an even larger cable and suggest 32/02.

16/02 layout wire showing the old Farnell electronic

codes

Poor soldered joints or loose screwed connectors will add

additional resistance to the circuit causing further voltage drops preventing

solenoids from operating. I have also read on the Internet that the quality of

the power supply is a factor. It is not just the maximum current that is

important but the ability of the controller or transformer to continue to

supply the power under load, i.e whilst switching the point. I will say that I

use Gaugemaster units which appear to me to have a reasonable pedigree and are

able to maintain their rated output under most load conditions.

Finally and perhaps most importantly, what about the

switches? Where switches designed or rated for 0.5amp are used to switch supplies

of 3amp there will be arcing and erosion of the contacts. As the damage

increases so will the resistance across the circuit in turn accelerating the

damage and leading to total failure of the switch. Perhaps my cheap push button

switches with a maximum current rating of 1amp are not suitable for the job?

A trawl of the Internet showed apparently similar looking

switches on offer from different sellers with maximum current ratings as low as

0.5 and even 0.25amps. So – something else to think about. My switches were

bought over a period of time from different sources. I am not knowing their

original specification. The latest batch of switches sourced from a UK supplier

claim to have a life of 30000 operations (at 1amp). This life will decrease

dramatically with higher currents.

In summary, Peco point motors installed under ideal

mechanical conditions should work quite adequately using reasonable quality

push button switches without the need for a CDU. When the mechanical loading

increases due the use of auxiliary switches or there is a need to move two or

more points simultaneously, simple switching becomes more problematic.

Similarly if the voltage cannot be maintained due to the length of cable runs

or the quality of the power supply then there may not be sufficient power

available at the motor to operate the points.

It is at this point that the use of a CDU becomes relevant.

Capacitors within a CDU build up a store of power which is

delivered as a single instantaneous pulse to the solenoid. The increased energy

assists in overcoming mechanical losses in the point mechanism. Typically the

instantaneous voltage from the CDU will be double the input voltage from the

controller compensating for voltage losses in the wiring. The CDU is recharged

relatively slowly compared to the switching action meaning that there is less

demand on the power supply from the controller or transformer. Lastly the pulse

of energy is of short duration, reducing the damaging load on the switch and

preventing burn out of the contacts.

I have also read that the rapid ‘snap action’ induced by the

capacitor discharge unit can be detrimental to the construction of the point.

Time will tell as to whether installing my CDUs has been a good thing!

Comments