No.104 A more Refined Grange –Hornby Bucklebury Grange.

It is a great feeling when things turn out well. Bucklebury Grange arrived at the beginning of summer.

Hornby Bucklebury Grange (left) Overton Grange

(right)

The first model was returned to the seller, something about

the way it ran. The replacement model was an improvement, so it stayed. How

many models can you send back? However at higher speeds it still seemed to roll

around. I began to imagine that one or more of the driving wheels was not

central on its axle. Bucklebury Grange was banished to one of the shed roads.

Now on RMweb RonnieS

has been investigating how to add some extra weight to a Hornby Grange. I would

have a look at Overton Grange (one that I added lead to earlier) and at the

same time, try and sort Bucklebury Grange.

Adding lead shot to the smokebox

Adding lead is relatively straightforward. I made a cylinder

out of a 65x65mm heavy duty brown paper which I pushed into the smokebox before

filling with around 50gm of lead shot. A bit like a cartridge case.

Adding lead beneath footplate and at the top of the

firebox

RonnieS

used some Blu-Tac to prove the space around the motor. I could add a slab of

lead to the top of the firebox (26x17/14mm) and some pieces beneath the

footplate (12x12mm). My lead was left over from house building work and seems

to vary in thickness between 2.5 and 3mm. The piece for the firebox is

trapezoidal, 17mm at the chimney end, 14mm at the cab end. The 12x12 pieces for

beneath the footplate will need to be individually shaped for the particular

model depending on how much glue Hornby has used to fix things in the cab. This

way I added about another 20gm. As bought Bucklebury Grange weighed 225gm.

Interestingly I could get Overton Grange and Derwent Grange up to nearly 295gm.

For Bucklebury Grange I could only get the weight up to 285gm. I do know that

there seemed to be more glue on Bucklebury Grange and that the pieces of lead

beneath the cab had to be smaller. Then of course the circuit board, screws and

blanking plug for DCC had been moved into the tender. As a comparison my 'new'

Bachmann Hall with lead added in place of a DC chip weighs in at 280gm.

Four into two is a squash

One unintended consequence of moving the digital chip to the

tender is that the number of wires between engine and tender increases from two

to four. I think that this has been overlooked by Hornby who have continued to

use the original ‘casting’ from the two wire models. I had to shave some plastic

off the body of Bucklebury Grange to enable it to sit comfortably without

damaging these wires.

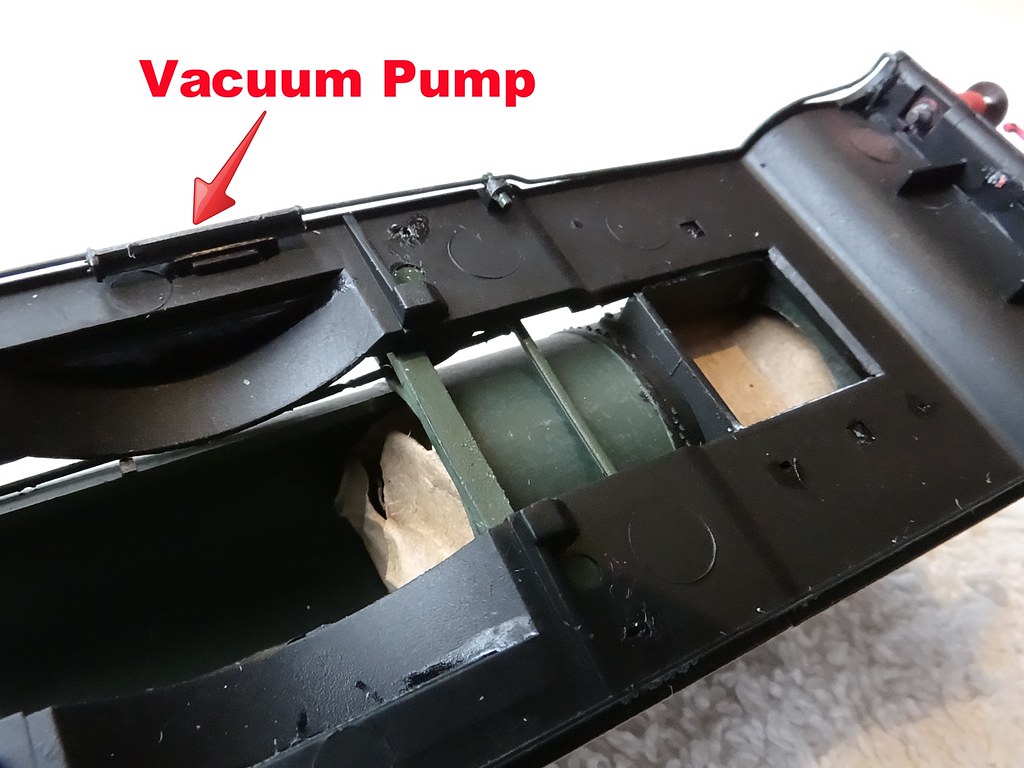

The new vacuum pump spindle

Seemingly all the new Hornby Granges from ‘Refined’ come

without vacuum pump spindles. There is a still a hole in the crosshead. I have

0.5mm twist drill bits. These are too big for the hole in the crosshead but can

be used by hand to open up the hole. I then selected one of my wife’s thinnest

dressmaking pins, cut the point off, trimmed it to 11mm and super glued it in

place. I think a very satisfactory solution.

Now, what about the vacuum pipe? If you go back to the view

at the top of this Post you will notice that there is something not quite right

with the vacuum pipe. It is funny how you can miss seeing faults when examining

a new locomotive.

Vacuum pipe as received

I don’t know, was it in the manufacture or in the packaging?

Either way, Butanone (MEK) is wonderful stuff and the offending pipe was cut

off, carefully reassembled and then reattached and painted.

Vacuum pipe reassembled

Vacuum pipe repainted – I would paint Penrice Castle at

the same time

How to improve the running?

Deconstructed!

Having spent so much time and effort on the appearance I

would put my hand in my pocket and purchase a new set of wheels. I am guessing

that these would be ‘old stock’ and not from Refined. Having taken Bucklebury

Grange apart it seems to me that all the major parts; motor, wheels, coupling

rods, gears are all completely interchangeable with the earlier Sanda Kan

produced models.

How does it run with the replacement wheels – fabulously.

Definitely a win win situation.

Hornby Bucklebury Grange – complete

I would say now – one of the best locomotives on the layout.

I wonder what the Shed Code should have been?

Comments