No.117 The Mainline Restaurant Buffet – Part Two, Close Coupling

My previousPost looked at some detail improvements to the old Mainline Restaurant Buffet including fitting Finecast Flush Glazing, wire handrails and simply filing the buffer heads.

Mainline RB slotted into a rake of BR Mk Is all fitted

with Hornby R8220 couplers

For me the most important improvement is the fitting of the

Bachmann close coupling mechanism. This enables the coach to be unobtrusively

slotted into a rake of Bachmann Mk Is – in my case all fitted with Hornby R8220

couplers.

Bachmann RU top, Mainline RB bottom

My first plan for improving the Mainline Restaurant Buffet

was to use a complete Bachmann RU underframe. Comparing the underside of the

Bachmann 39-101 derivatives with the Mainline vehicle showed a great deal of

similarity. The Mainline truss detail is perhaps heavier but when viewed from

the side I don’t think there is much to choose between the two models. Either I

would have to remove the corridor ends from the Bachmann underframe or

carefully cut the ends out of the Mainline body shell. Neither seemed a good

idea – and why ruin a perfectly good Bachmann RU?

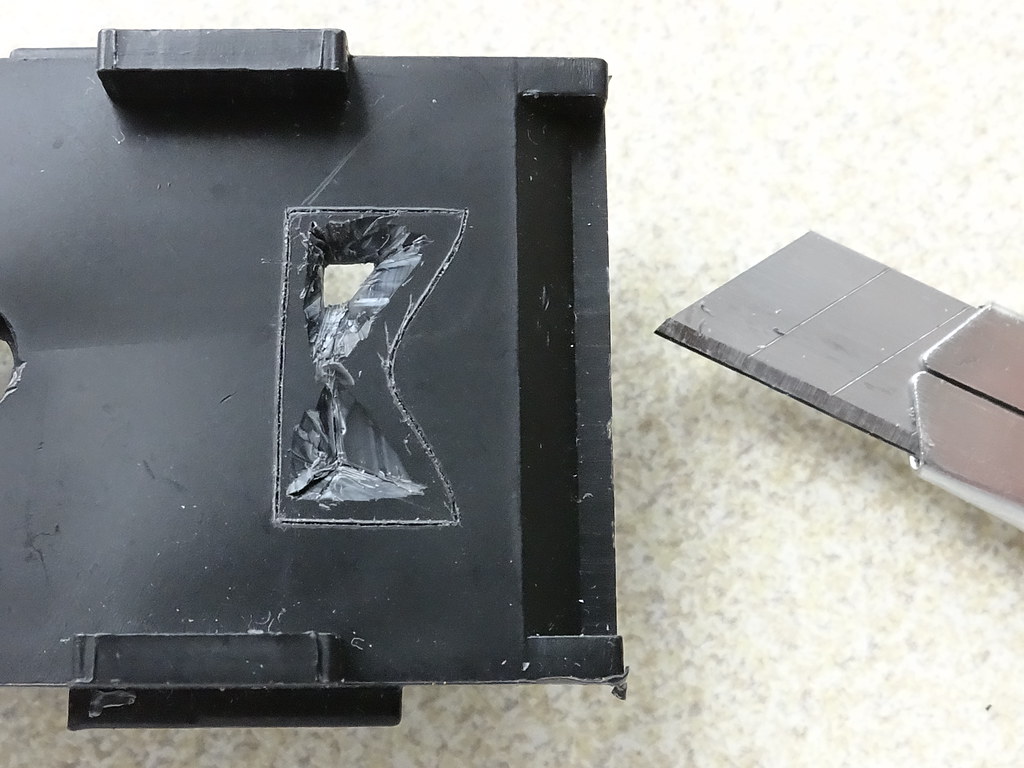

Transferring the shape of the opening

Plan B would be to use the Mainline underframe suitably

modified to accommodate the Bachmann close coupling mechanism. The view above

shows the template I made to transfer the slot size for the close coupling

mechanism from the Bachmann vehicle to the Mainline underframe. The template

lines up with the inside edge of the Bachmann corridor end so that it can be

placed up to the open corridor end of the Mainline frame. I used the points from

a pair of dividers out of my box of drawing instruments to mark the plastic.

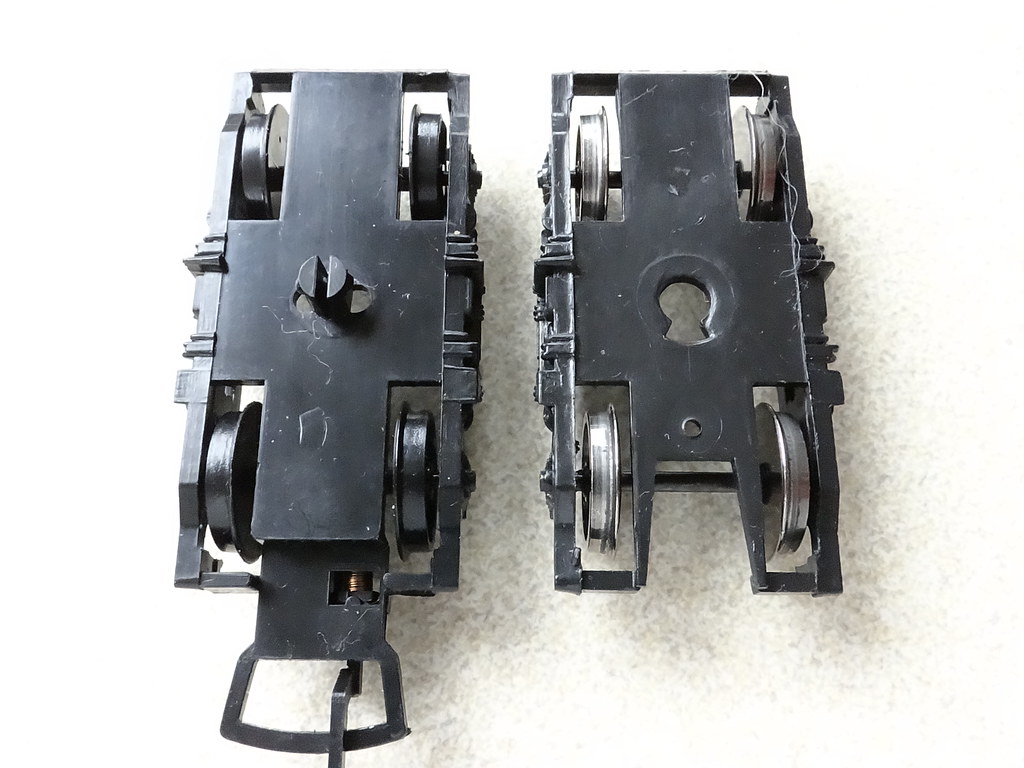

Mainline bogie top, Bachmann bottom

I had set aside a spare pair of Bachmann Commonwealth bogies

for the project. However the detail on the original Mainline bogies is very

good and when fitted with Bachmann metal disc wheels there is little to choose

between the running qualities of the two bogie types.

Mainline left, Bachmann right

Viewed from above the Mainline fixing is completely

different to the later Bachmann models. If I was keeping the Mainline

underframe the only sensible option was to reuse the Mainline bogies!

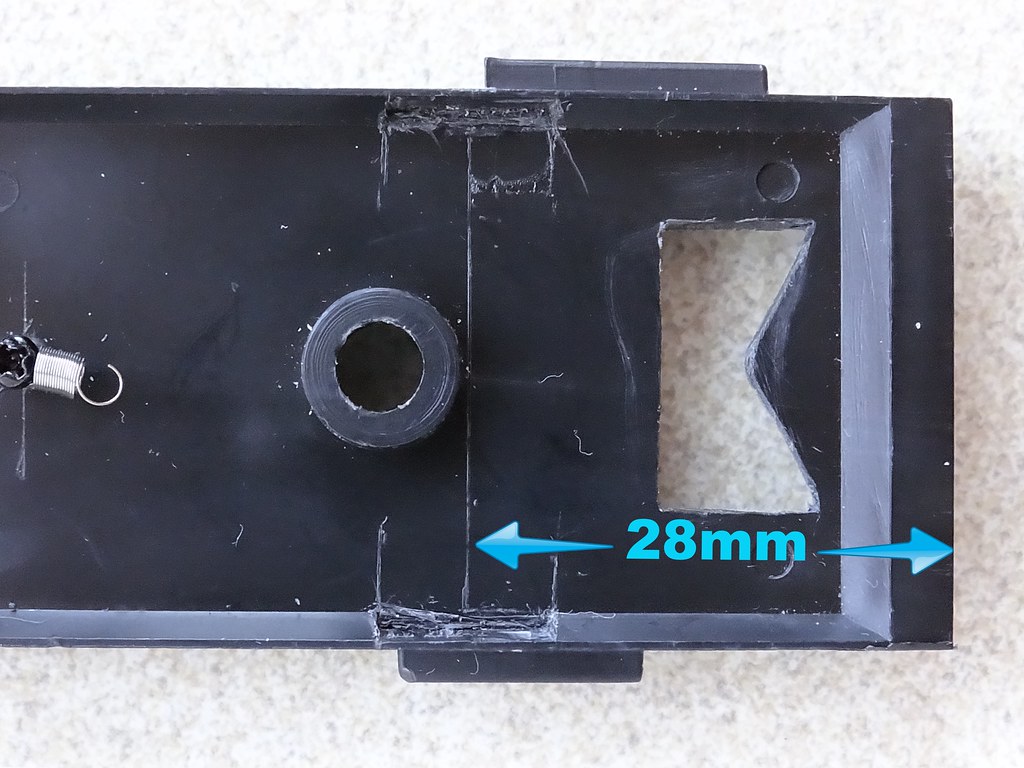

Cutting the slot for the Bachmann close coupling

mechanism

Back to the Mainline underframe and I cut the slot for the

close coupling mechanism by paring away the soft plastic with a ‘snap off

blade’ type craft knife – finishing the edges off with a small file.

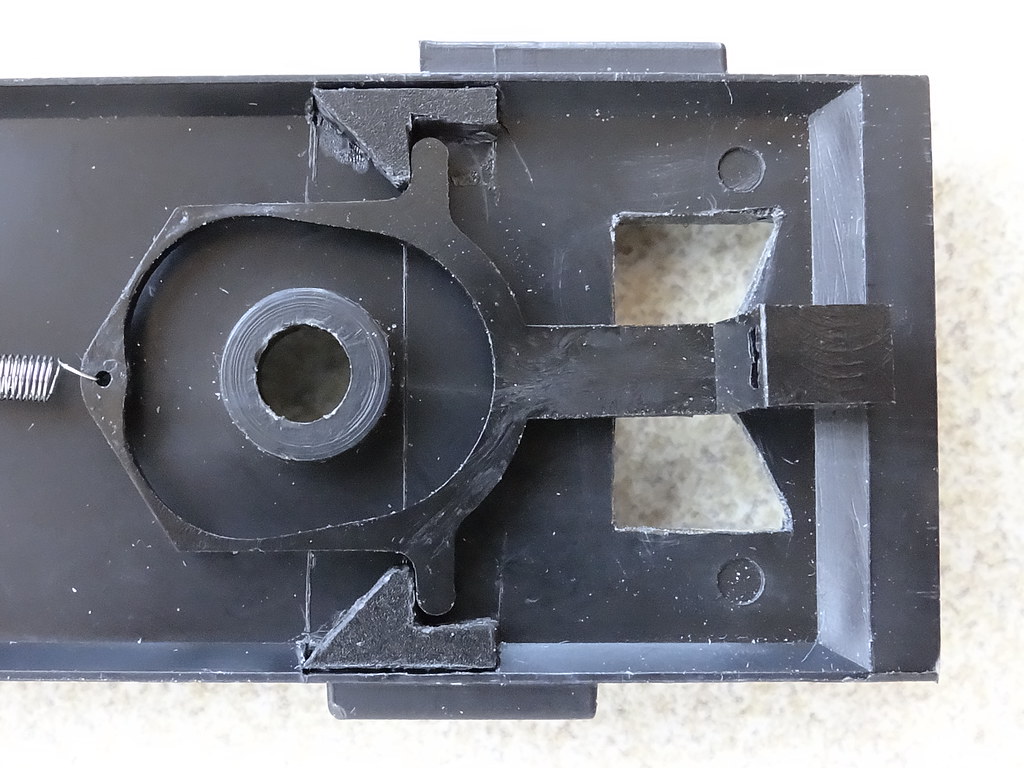

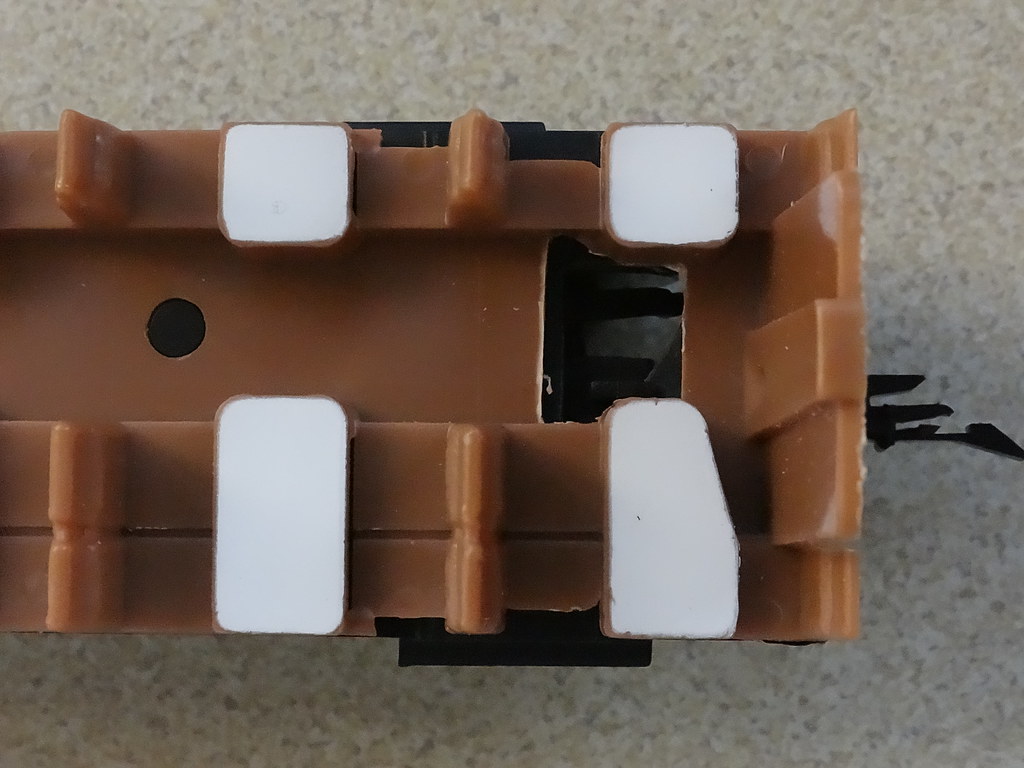

Pockets for pivot points

The same knife was used to hollow out pockets for the pivot

points – taking great care not to cut through the outside edge of the

underframe. I positioned the mid point of my pockets 28mm back from the end of

the Mainline underframe, the pockets themselves being 10mm long. The pivot

points were built up and shaped from two layers of CD case plastic 5mm x 10mm.

These can be fitted in the pockets and tried for shape and ease of operation

with the Bachmann coupling mechanism before fixing in place with Butanone. I

also drilled a small hole for one of Bachmann’s tiny screws to attach the

tension spring for the coupling mechanism.

The finished mechanism

I didn’t have a spare Mk I coupling mechanism. Instead I

used the mechanism from a Mk II coach. ‘Andrew’ at Peter’s Spares deserves

special mention for sorting out my order when I failed to buy a pair and had

completed the online payment procedure for just one coupling mechanism.

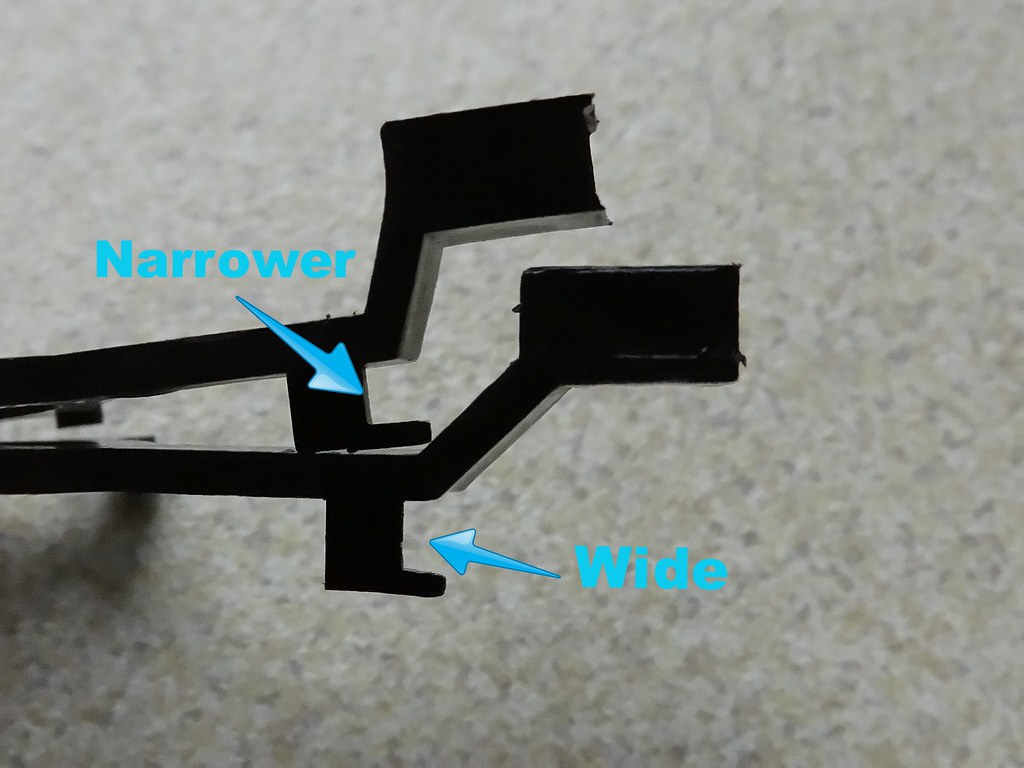

Mk II left, Mk I right

The Bachmann Mk I and Mk II coupling mechanisms are subtly

different.

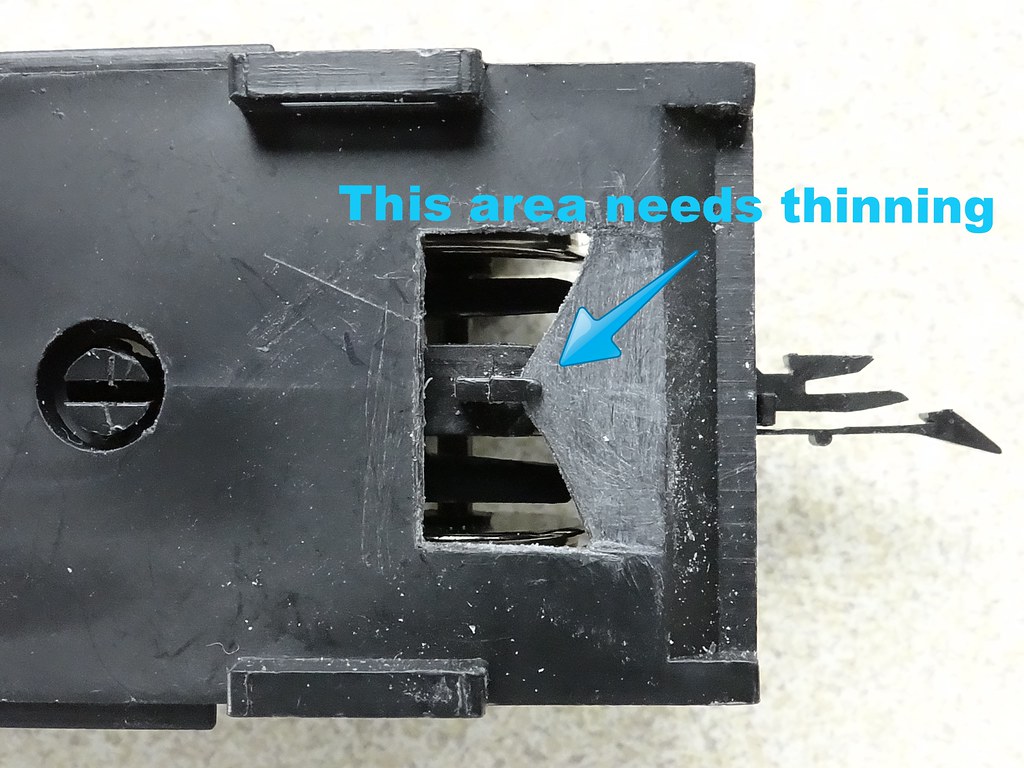

Mk II top, Mk I bottom

Significantly the Mk II coupling mechanism is designed to

operate with a thinner floor. I used a combination of file and knife to thin

the Mainline underframe / floor. This is very necessary for the smooth

operation of the coupling and also assists in lining up the coupling pocket to

the same height as for other Bachmann Mk I coaches. I have to admit that I also

applied a little bit of bending to the coupling pocket to assist in this

levelling process.

Finished

I had concerns that the seating unit would interfere with

the close coupling mechanism so I cut a slot in the floor. In practice I think

I was over cautious and only needed to file off a little of the plastic on the

underside of the floor.

Slot cut in floor over close coupling mechanism

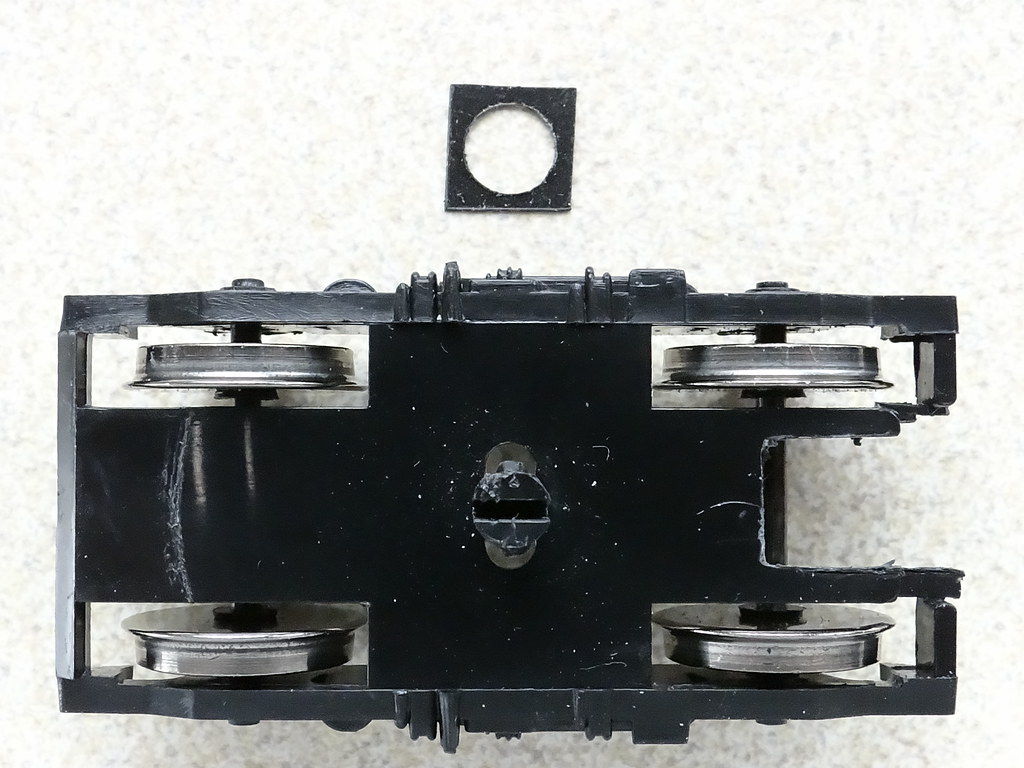

Finally I cut the Mainline couplings from the bogies and

formed a slot to mimic the slot in the Bachmann bogies to accommodate the

coupling mechanism.

Mainline bogie adapted for use with Bachmann coupling

mechanism

Again there is some trial and error to make sure that the

cut edges on the bogie are smooth and allow free movement of the coupling

mechanism.

I decided that the roof line on my model was low and I added

a packing piece cut from a file divider between the bogie and the underframe.

The roof line is now fine but the buffers are a touch high –

compared to Bachmann Mk Is. Life is a compromise.

Bachmann Mk I left, Mainline RB right

This was not a quick conversion. On the other hand it was

all carried out on ‘the kitchen table’ with simple tools. I think a good

outcome.

Addendum 25.07.15

After running the RB for a number of weeks I have now removed the packing piece that I had inserted between the coach and the top of the bogie. I guess it is all in the eye of the beholder?

Addendum 25.07.15

After running the RB for a number of weeks I have now removed the packing piece that I had inserted between the coach and the top of the bogie. I guess it is all in the eye of the beholder?

Comments