No.129 Hornby’s Class 52xx tanks - variability

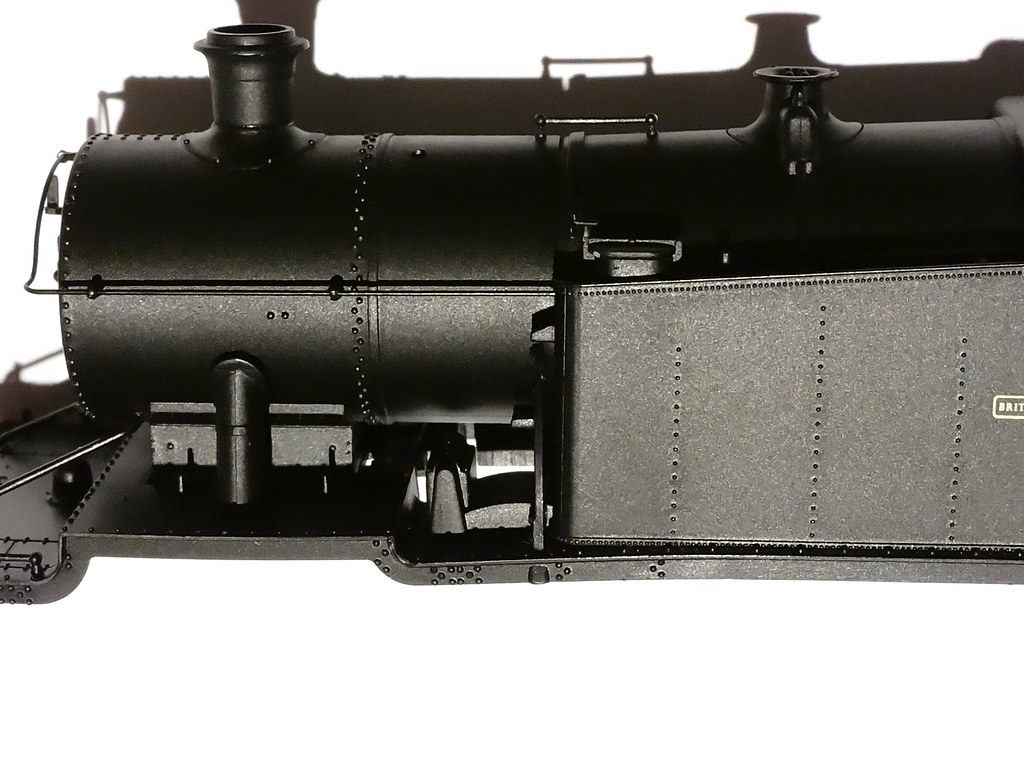

The New Year has heralded a crop of new models. It is also the time of year when manufacturers and retailers clear out old stock. I have given in to temptation and I have purchased a second Hornby Class 52xx tank – ‘5239’ (R3224). My new model has a curved footplate to complement my existing model with its straight footplate.

Hornby Class 52xx R3224 ‘5239’ with curved footplate over

cylinders

It would have been back in August 2013 when I took delivery

of ‘5243’, one of Hornby’s first batches of Class 52xx ex GWR tank engines,

R3126. It is a good looking engine with some very fine detail but

I noted that the buffers were not sprung and the smoke box dart was moulded

integrally with the smokebox door.

Hornby Class 52xx R3126 ‘5243’ with straight footplate

To their credit, Hornby have now provided the latest 52xx

models with a separate detailed smoke box dart. However we still await the

sprung buffers.

The Hornby range includes a number of Class 42xx, Class 52xx

and Class 72xx locomotives. Sometimes the differences are obvious. For example

the Class 72xx has an extended bunker supported by an extra pair of trailing

wheels. My original Class 52xx ‘5243’ (R3126) looks identical to Hornby’s

latest Class 42xx ‘4257’ (R3223) – that is except for the detailed separate

smokebox dart on the newer model. Perhaps the difference between the Class 42xx

and the 52xx is simply the number series, 4200 – 4299 for the Class 42xx and

5200 – 5264 for the Class 52xx. But then why do some engines have a curved

footplate raised above the cylinders?

I would research the matter.

First a look at my 1960 ‘bible’ by authors Casserley and

Asher (Ref.1). They refer to Class 42xx/Class 52xx as a single

class but there is no specific mention of straight or curved footplates:

Number series: 4200/1/3/6-8, 4211-5/7/8, 4221-33/5-8,

4241-3/6-8, 4250-4299, 5200-5264

Churchward 2-8-0T's, 4'7½ wheels, for heavy

short-haul mineral traffic, built 1910-40. In all, 205 engines were constructed

to this design: Nos. 4200-4299 and 5200-5294 between 1910 and 1930, and a final

10 in 1940. In 1934, Nos. 5275-5294 were reconstructed as 2-8-2T's and

renumbered 7200-7219, while in 1935-6 Nos. 5255-5274 were similarly treated and

became Nos. 7220-7239. These were followed in 1937 by 14 more reconstructions

from the earlier locomotives, which were duly renumbered 7240-7253, their

original numbers having been 4239, 4220, 4202, 4204, 4216, 4205, 4234, 4244,

4249, 4209, 4219, 4240, 4210 and 4425 respectively. Rather strangely, ten

further engines were built in 1940 as 2-8-0T's, numbered 5255-5264, but they

are, of course, entirely different engines from those which at first bore these

numbers, and which are now 2-8-2T's, Nos.7220-7229. Several of the 4200 series

were scrapped during 1959.

I also visited the

Great WesternArchive (GWA) web site.

Again both the 42xx and the 52xx number series are grouped

together as a single class referred to as the 4200 tank class. I have condensed

the following points from the GWA.

Running numbers: 4200-4299, 5200-5264

The prototype 2 - 8 - 0T ‘4201’ appeared in 1910 with a

straight backed bunker and no top feed.

The first production batch had a top feed and the rear

edge of the bunker was extended to increase the coal capacity. Production

continued up to number 4299 and then from 5200-5204, finishing with the

completion of ‘4200’ in 1923.

For the second phase of construction the cylinder

diameter of numbers 5205- 5294 was increased from 18½ inches to 19 inches. The

resulting increase in tractive effort meant that engines from number 5205 were

referred to as the '5205' class. The GWA states that these engines could be

identified by their outside steam pipes.

Towards the end of construction whilst building numbers

5275-5294 there was a reduction in coal exports which caused many of the class

to lie idle. The relatively small size of the coal bunker restricted use of the

engines and they were placed into storage at Swindon. Collett decided to

increase the coal capacity and altered the batch 5275-5294 to a 2 - 8 - 2T

configuration. The modified engines were renumbered and designated '7200'

class.

Further '7200' class engines were requested and the 20 next

newest engines, numbers 5255-5274 were also rebuilt as 2 - 8 - 2T's. Even more

2-8-2Ts were requested and random engines appear to have been taken from the

earlier Churchward '4200' series.

Rebuilding the last of these '4200' class ceased at the

end of 1939 and was followed at the beginning of 1940 by construction of a

further batch of the '5205' class, numbers 5255-5264.

The GWA states that when new cylinders were required on

the '4200' engines, outside steam pipes were also fitted. Some engines at this

time were given a curved front frame which included raising the height of the

cylinder and therefore raising the running plate above the cylinder. However

not all engines were modified in this way. Similarly, some members of the

'5205' class fitted with outside steam pipes as standard had a flat running

plate whereas most of the newer engines of this series had raised cylinders and

therefore a raised running plate.

The notes above paint a rather confused picture. However I

would say that it is well known that Castle Class and Hall Class engines

coupled with Churchward tenders could enter Swindon Works for a major overhaul

and emerge later coupled to a flat sided Hawksworth tenders (and vice versa).

From personal experience in the north east of England it was also common for

J26 Class engines with circular spectacle plates to the cabs to emerge from Darlington

Works with a cab with straight sided spectacle plates from a J27. Might it be

that when visiting Swindon Works for a major overhaul the frames and cylinders

from engines in the series 5205-5264 were swapped with bits from engines in the

series 4200-4299 and 5200-5204?

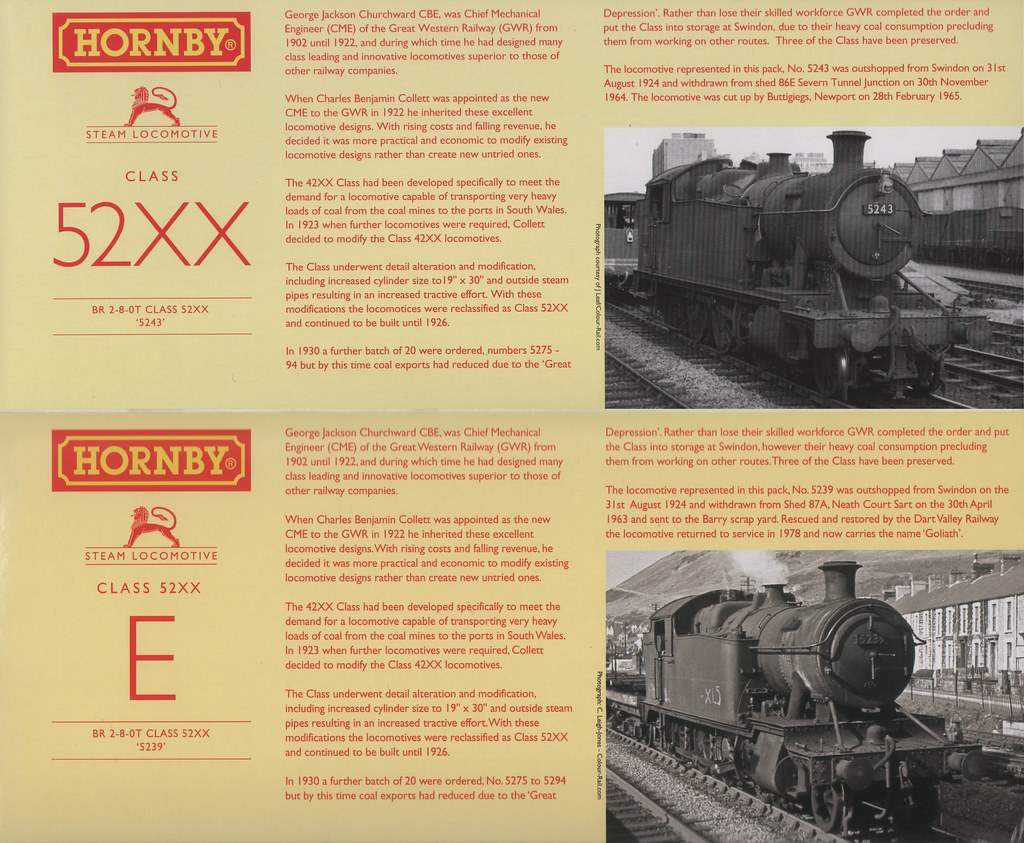

Hornby Class 52xx Packaging – R3126 (top), R3224 (bottom)

In these circumstances photographs become exceedingly

valuable providing a definitive means of identifying the shape of running plate

for a particular locomotive at a given point in time. The notes on the rear of

Hornby’s packaging include a copy of a photograph of the enclosed model. ‘5239’

(R3224), one of the later production batch is pictured with a curved footplate

and running with a late crest. In contrast sister engine ‘5243’ (R3126), with a

higher running number, is pictured again with late crest but this time with a

straight footplate. Whilst not shown here the packaging for ‘4257’ (R3223) an early

engine, pictures the engine with late crest and I am guessing its original

straight footplate.

What about my new Hornby model?

Hornby 52xx R3224 ‘5239’ – footplate as received

My model arrived with noticeable bend in the straight

section of the footplate. Trawling through other people’s pictures including

an image of the model on Hornby’s web site I can imagine that there is a

production fault with the model that is preventing the footplate lying

properly.

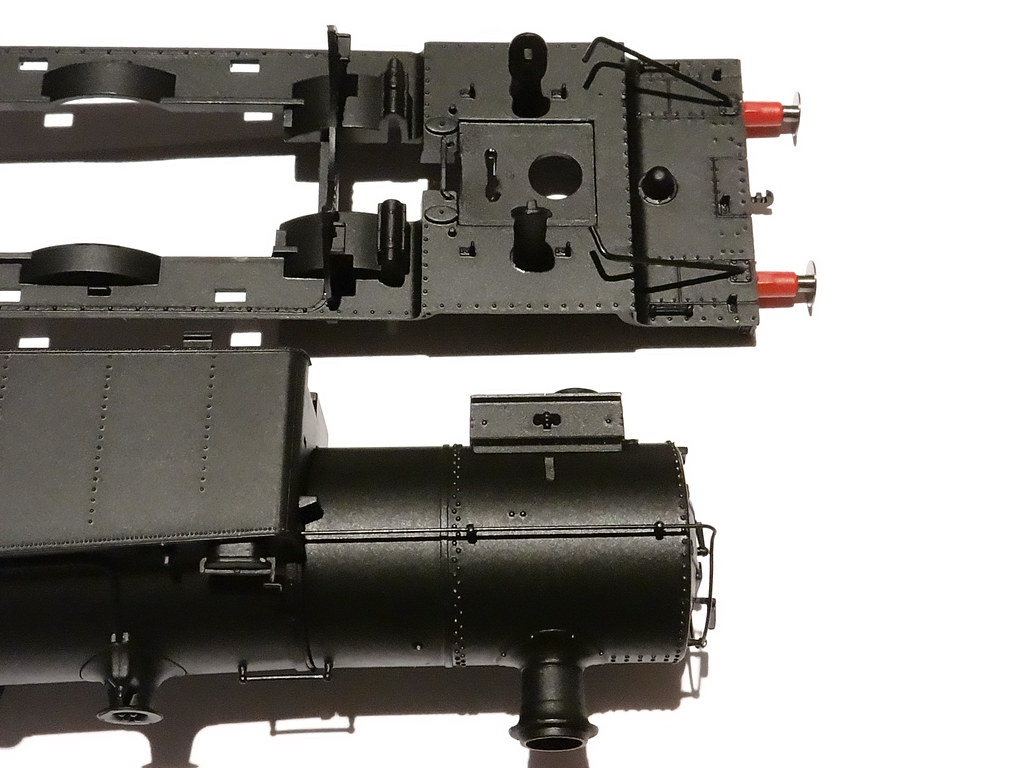

The footplate can be unclipped from the side tanks. The only

glue used to hold my model together was on a tab beneath the smoke box which I

cut round and prised apart.

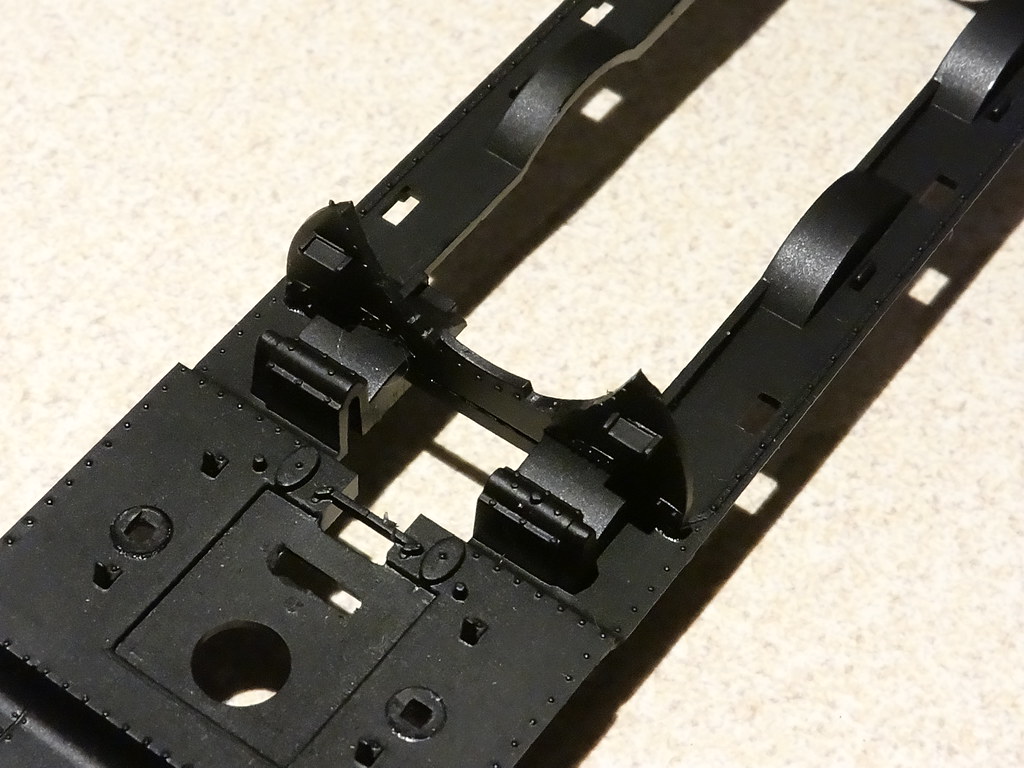

Hornby 52xx R3224 ‘5239’ – unfolding the ‘outriggers’

The front ‘stays’ or ‘outriggers’ are a push fit into holes

at the front of the smoke box. These can be swung out of the way to allow the

footplate to separate completely from the smokebox/boiler/side tank moulding.

Hornby 52xx R3224 ‘5239’ – shave the motion bracket

Having dismantled the body shell I set about trying to

identify features that might be interfering with the fitting of the footplate.

I should say that I could not identify a single cause and set about carefully

shaving plastic from areas that I thought might be acting as ‘high spots’.

Because of Hornby’s ‘clip together’ method of construction I was able to

reassemble the footplate and check the effect of each operation before

proceeding too far.

Hornby 52xx R3224 ‘5239’ – gently file around the base of the smokebox saddle

I was particularly suspicious about the base of the smokebox

saddle. Rather than remove plastic from the saddle I would have preferred to

cut through the matching opening in the footplate. However because of Hornby’s

method of assembly I thought that removing the opening would leave the front of

the footplate with too little support – I didn’t want to risk it.

Hornby 52xx R3224 ‘5239’ – shortened steam pipes

It did become obvious on my model that the steam pipes were

too long. On my model these pipes were a push fit into the sides of the smoke

box and it proved relatively easy to prise the glued end of the pipes out of

their sockets in the footplate. The pipes were shortened by approximately 1mm.

I took particular care to preserve the square spigot. Subsequently the pipes

were reassembled without the need for any glue.

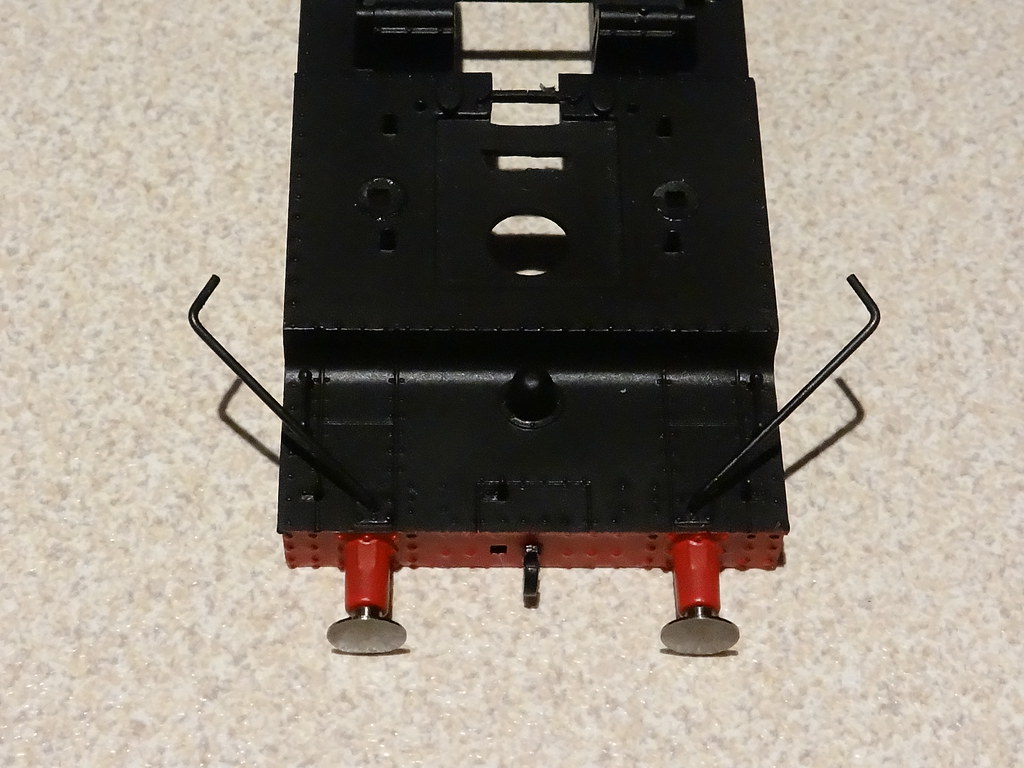

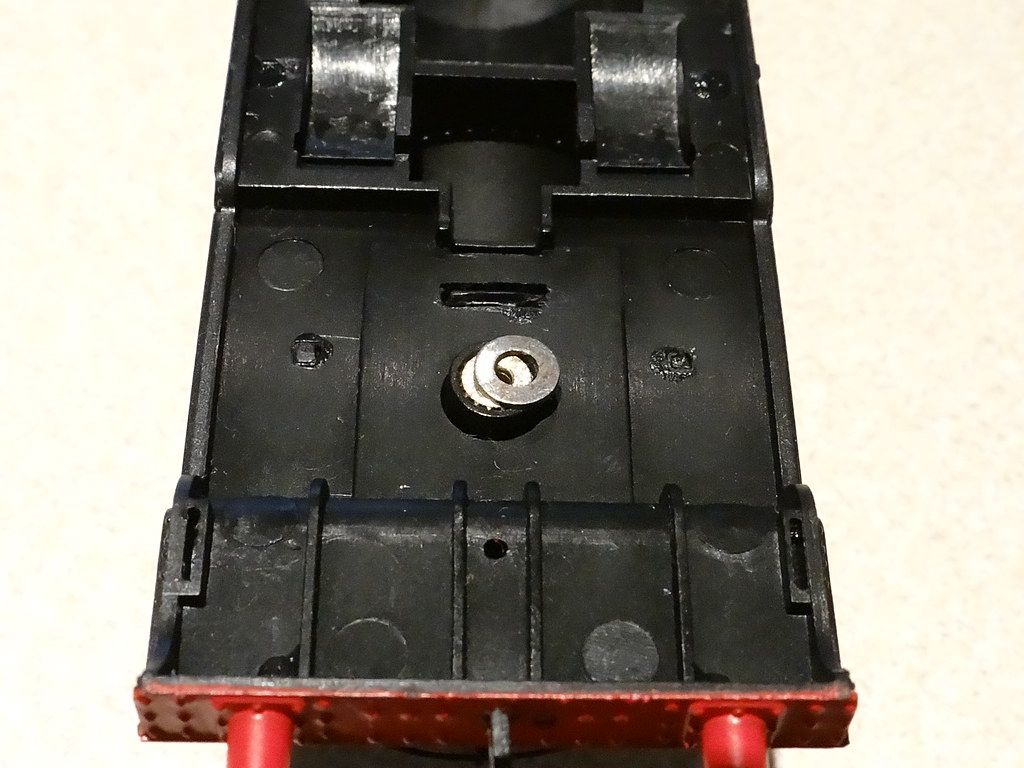

Hornby 52xx R3224 ‘5239’ – packing washer placed beneath smokebox

Finally I threaded a couple of thin washers onto the fixing

screw beneath the smokebox. The total thickness of packing would be around 1mm

similar to the original distortion in the footplate and also to the amount

removed from the steam pipes.

The proof of the pudding, Hornby 42xx R3233 ‘4257’(Left), Hornby 52xx R3224 ‘5239’(Right)

Nearly very good? As the view above shows I have removed the

worst of the distortion and the buffers still sit at the correct level.

Hornby 52xx R3224 ‘5239’ – a nice looking model

As I said at the start of this post –I still think a nice

looking model. It would be interesting to know whether the distortion to the

footplate that I experienced was a Quality Assurance issue during assembly or

whether as I suspect a design / production error perhaps associated with the

use of common parts for both the straight footplate model (R3126/R3223) and the

curved footplate variety (R3224)?

Reference

1. Casserley HC and Asher LL (1961) ‘Locomotives of British

Railways’ (Spring Books)

Comments