No.136 My Deltic Sound Project

Continuing the north east theme I have invested in a

Bachmann Deltic of the two tone green variety. I had to cancel an order on eBay

when a quick check revealed that

the Deltic Preservation Society still had ‘The Green Howards’ in stock (and

many more Bachmann models) at very competitive prices, frequently below the

cost of second hand items on that well known auction site.

Bachmann D9008 The Green Howards – Limited Edition for

the Deltic Preservation Society

After recent successes with running Bachmann sound

locomotives on DC Analogue I thought that a sound fitted Deltic would

complement my existing Class 40 and Class 45 models. I would add digital sound

to my model,‘The Green Howards’.

Speaker cavity in Deltic ‘The Duke of Wellington’s

Regiment’ – Note factory hard soldered connections for cab lighting

Bachmann have produced a factory fitted digital sound Deltic

and the metal chassis has a shallow cavity machined in the top for a speaker.

Recent Bachmann Deltics have a 21 pin socket and the factory fitted sound model

is fitted with an ESU LokSound V4.0 chip. The perceived wisdom is that this

‘standard’ sound system does not capture the deeper notes so characteristic of

the prototype locomotive. How to proceed?

Standard speaker packaged with ESU / LokSound V4.0

There are numerous articles on the internet for improving

the sound quality of the Bachmann model. Fundamental to all these suggestions

is the need to provide as big a speaker as possible. One of the earliest

articles was by Ian Harper of Peasholm Models (Railway Modeller January 2010)

and currently available on the Olivia’s Trains web site. Ian recommended a bass reflex

speaker fitted within the tanks. I noted that the speaker was fitted pointing

up into motor cavity without the need to make any openings in the base of the

Deltic fuel tanks. A negative point as far as I was concerned was the need to

remove metal from the base of the chassis and to lose the ballast weight from

within the tanks. The latter weighs some 75g – a significant lump!

‘The bass reflex speaker in the tanks’ approach has been

taken a stage further by Legomanbiffo and

on RMweb there is thread with a detailed guide for increasing the

effectiveness of such a speaker. In this approach the base reflex speaker is

fitted pointing downwards and a new reflex tube is fabricated to fit alongside

the speaker. I noted that the size of the bass reflex speaker was limited by

the presence of the reflex tube. I also noted that there were significant modifications

needed to the Bachmann fuel tanks requiring tools and levels of skills not

readily available on our kitchen table. I would look for another approach.

Technology moves on and new speakers are constantly becoming

available. Could I fit a ‘sugar cube’ speaker in the top of the chassis?

Probably - I could utilise the cavity provided by Bachmann and I would not need

to dismantle the model or lose any ballast from the tanks. One downside would

be the need to reroute and lengthen the existing wiring for lights and power

from the bogie running across the top of the chassis. My research on ‘sugar

cube’ speakers took me to the YouChoos web site where I discovered some 6mm

deep 8 ohm ‘bass’ speakers reportedly producing a fuller sound than the sugar

cube speakers. There are

instructionson how to fit these speakers into a Bachmann Deltic. I noted that the

speakers were installed facing downwards with holes drilled through the base of

the Bachmann tanks. YouChoos favour Zimmo decoders which are shown matched with

8 ohm speakers. The LokSound V4.0 chip is engineered to work with a 4 ohm

speaker. From my school days for resistors in parallel (R1 and

R2) the total resistance RT is calculated as follows:

1/R1 +1/R2 =1/RT

Hence for two 8 ohm box speakers:

1/8Ω+1/8Ω=1/4Ω

If I wired the two 8 ohm bass speakers in parallel, the

combined resistance is 4 ohms – just right for the V4.0 decoder. I had a plan.

I would buy a LokSound chip from my usual supplier, loaded

with their Class 55 project. Thank you Kevin at Coastal DCC. I then purchased a

pair of YLR-302506 8 ohm bass box speakers from YouChoos.

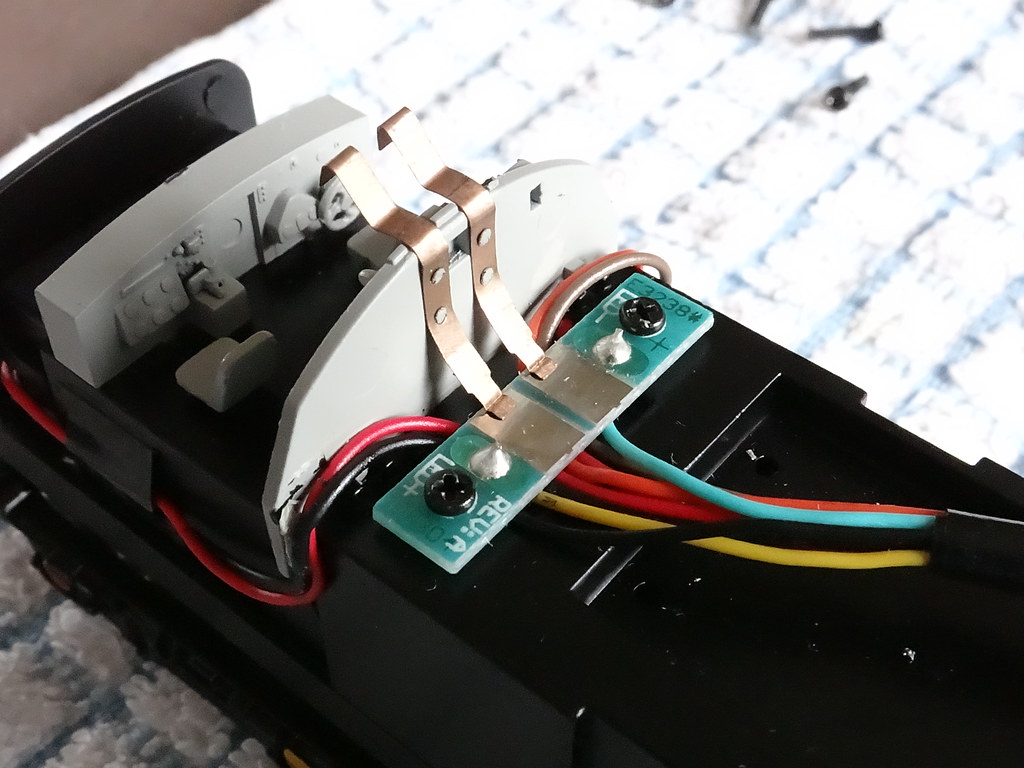

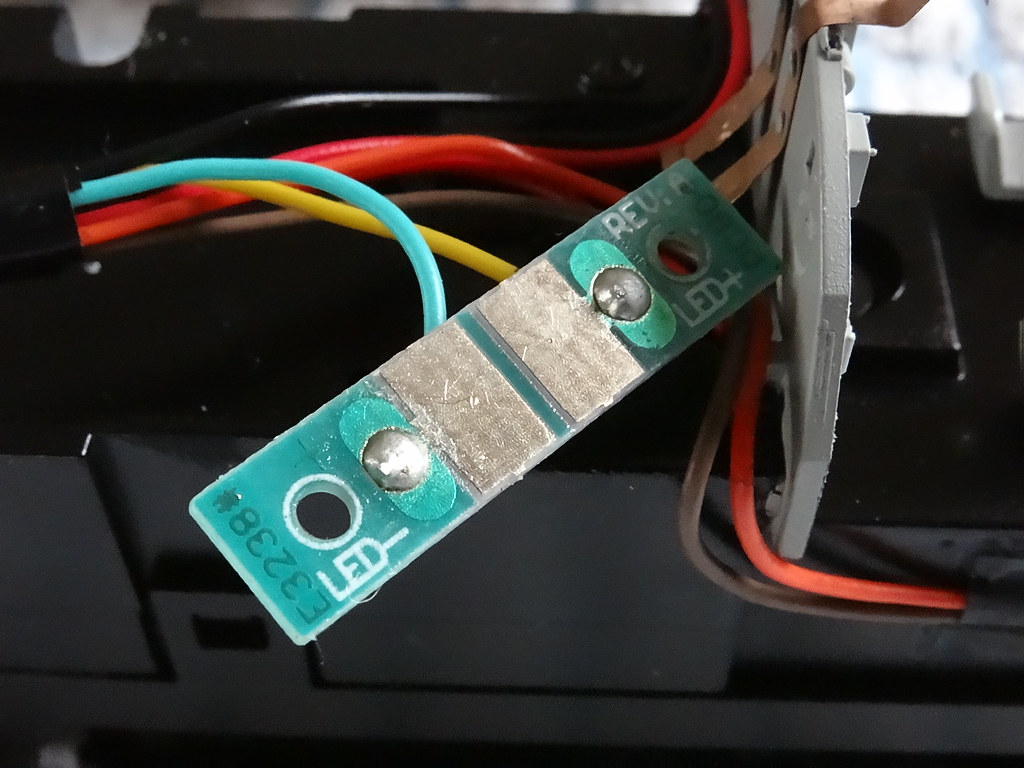

Contacts for cab lighting - Bachmann D9008 The Green

Howards

First a word of advice. Before even thinking about

disconnecting wires and PCBs it makes a lot of sense to check the fixity of the

two pairs of copper contacts on the back of the Deltic cab walls which are for

the cab lights. Even if these appear to be in perfect working order I would

suggest adding a few spots of Super Glue to keep these contacts in place during

the subsequent works.

Having ‘checked’ the fixity of the contacts for both cabs,

the chassis can be dismantled. If your model is like ‘The Green Howards’ you

are lucky. In this case the contacts rely simply on the spring resistance and

do not hinder dismantling. If on the other hand the contacts have been factory

soldered then there will be a short delay in proceedings whilst these joints

are unsoldered to enable the Little and Large PCBs to be unscrewed and lifted

clear of the metal chassis.

Little PCB unscrewed

You are now rapidly approaching 'the point of no return’.

Armed with a paper and pencil to note the colour of wires, the power leads

marked L and R from the bogies can be unplugged from the Large PCB. With the

wires disconnected the top retaining screws for the bogies can be removed and

the bogies carefully pulled out from the chassis. At this point I actually

screwed the Large PCB back in place as a temporary measure whilst I prised up

the four plastic tabs that are used to attach the lower chassis and tank

moulding to the metal chassis.

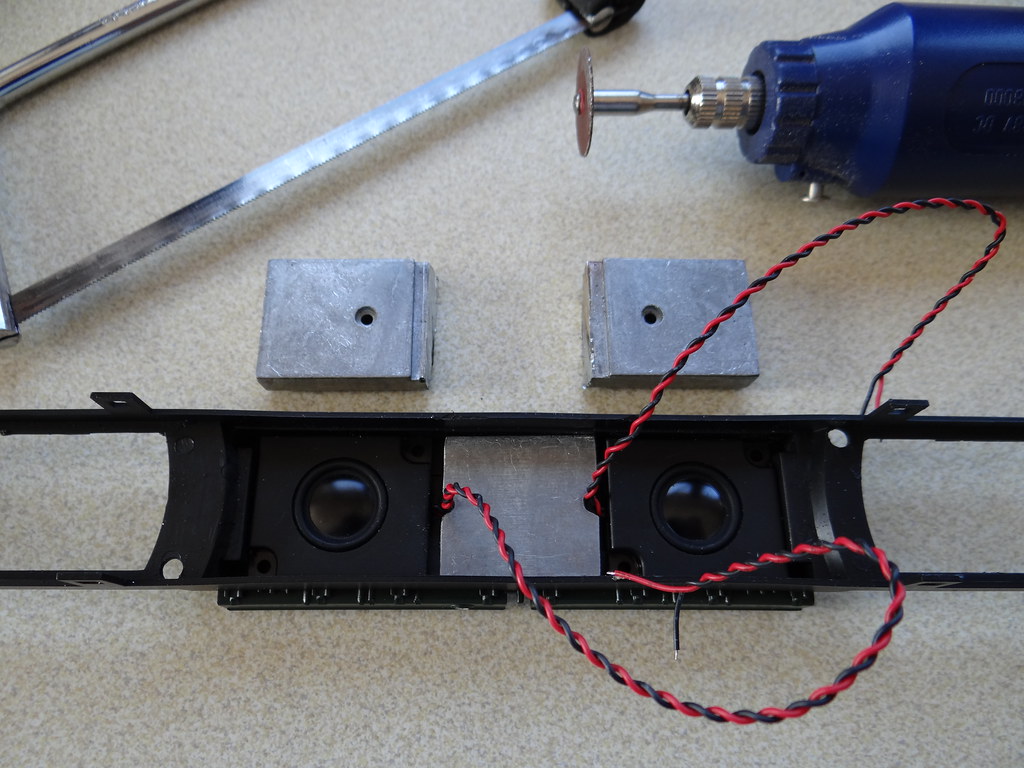

The tank weight

Once the plastic chassis is separated from the metal chassis

the internal weight from the fuel tanks can be unscrewed and plastic fixings

removed – I used a miniature cutting disc. Using the box speakers as a cutting

guide, the ballast weight was marked out and then cut into three pieces with a

hacksaw. The centre piece which I retained was notched with the miniature

cutting disc to accommodate the speaker wires.

Trial run – fitting the speakers

The underside of my speakers had a metal disc which

protruded about 0.5mm from the centre of the plastic box. I used my Dremel type

drill to remove some of the plastic in the tank base to allow the speakers to

sit flat. I would follow Ian Harper’s advice and have the speakers pointing

upwards with the sound filling the cavity for the drive shafts and escaping

around the bogies.

Inside of the tanks prepared

After separating and straightening the red and black speaker

wires I used double sided tape to fix the speakers and the remaining centre

portion of the ballast weight back into the fuel tanks. With an eye on the

finished article you need to group the two black and the two red speaker wires

together by colour, black to one side and red to the other. A little bit of

black insulating tape will not come amiss.

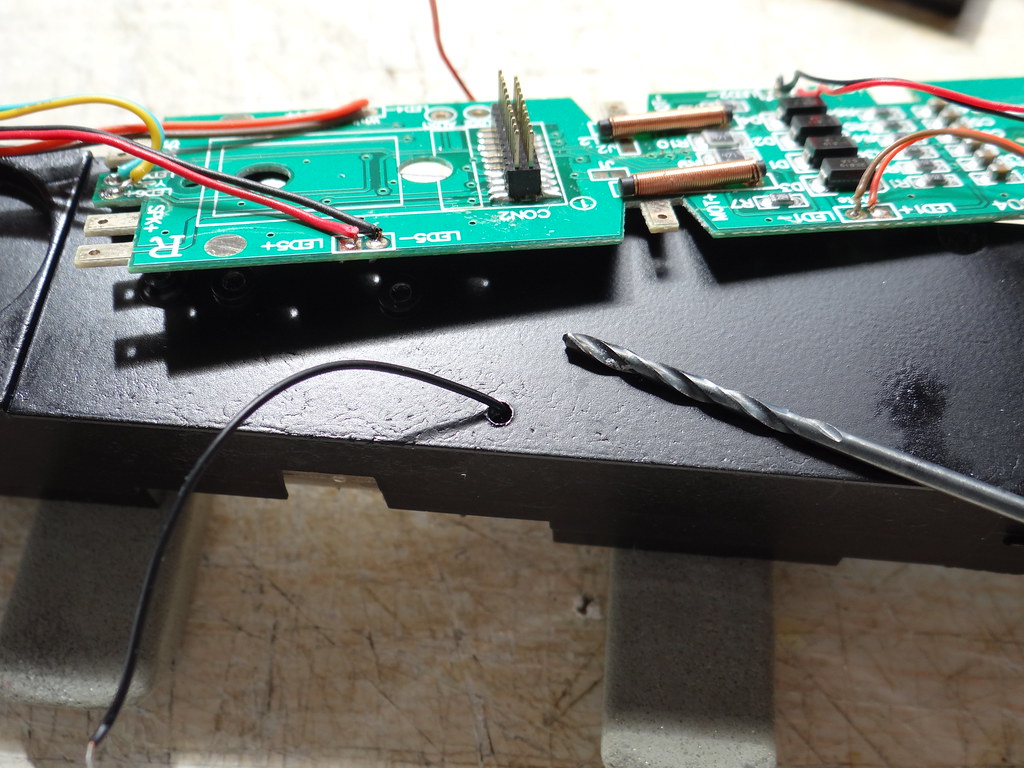

Enlarging the hole for the motor wires to accommodate the

speaker wires

At this point I turned my attention to the metal chassis and

unscrewed the Large PCB (again). This time I disconnected and unthreaded the

two leads to the motor. With the wires unthreaded I ran a drill through the

hole in the metal chassis. I didn’t make a note of the sizes but the first pass

was made with a bit essentially the same size as the existing hole. This was

followed by a second pass using a drill bit one size higher, maybe 3/32 and

just large enough to accommodate one motor lead and two straightened speaker

wires. You will note that I was able to carry out this work without disturbing

the motor which I thought was a big plus.

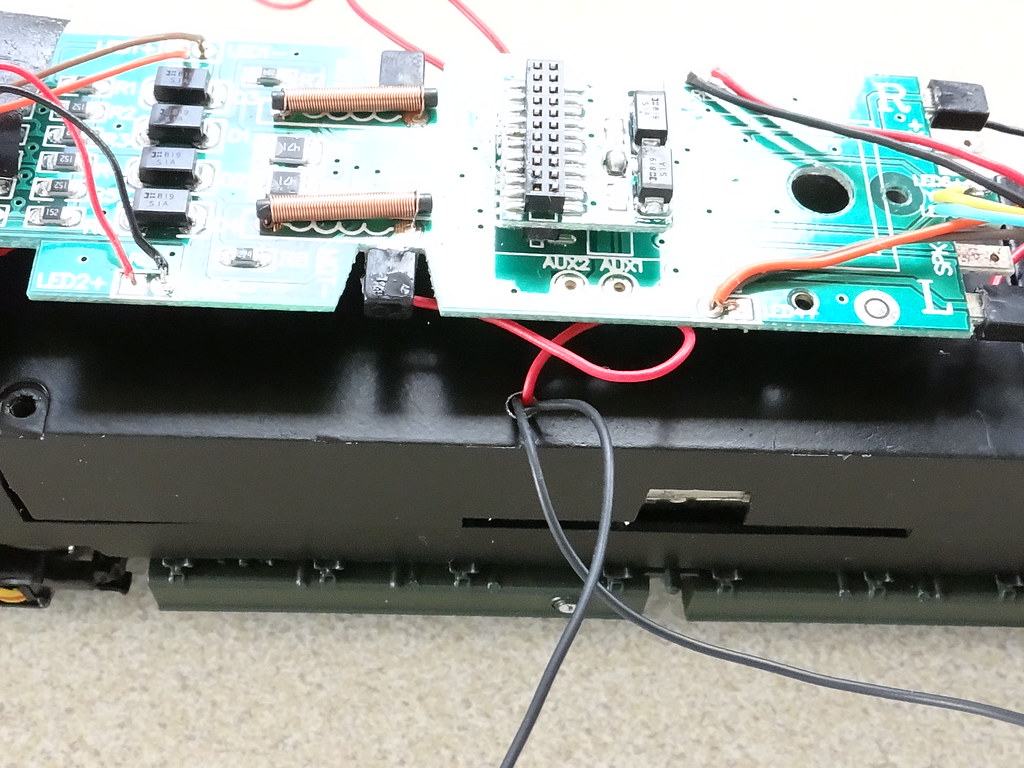

Motor reconnected and two black speaker wires showing

After reconnecting the leads for the motor I then fed the

two black speaker wires up besides one motor lead and the two red leads up

besides the other motor lead. I don’t think it matters which hole you choose as

long as you keep the speaker leads with the same colour together. With the all

the leads threaded through to the top of the chassis it is time to offer up the

plastic chassis with the speakers to the metal chassis and to clip the parts

back together. Care needs to be taken to ensure that the new speaker wires are

not trapped by the motor and I used some black insulating tape to pull the

wires to the sides of the fuel tanks. Like me you might wish you had more

delicate fingers and better eye sight!

With the fuel tanks reattached it is time to refit the

bogies, first rethreading the power leads, then engaging the drive shaft before

carefully pulling through the surplus power wires and screwing the bogies back

in place. It took me a couple of attempts to get the power leads fully through

the chassis block without leaving any surplus curled up on top of the bogie.

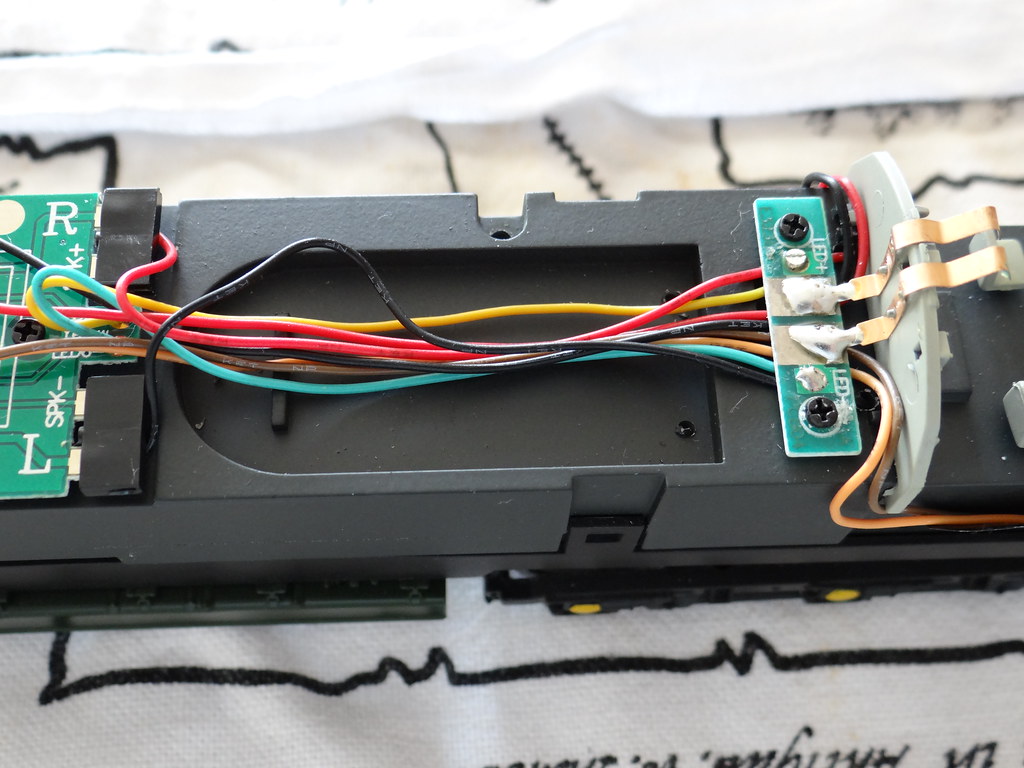

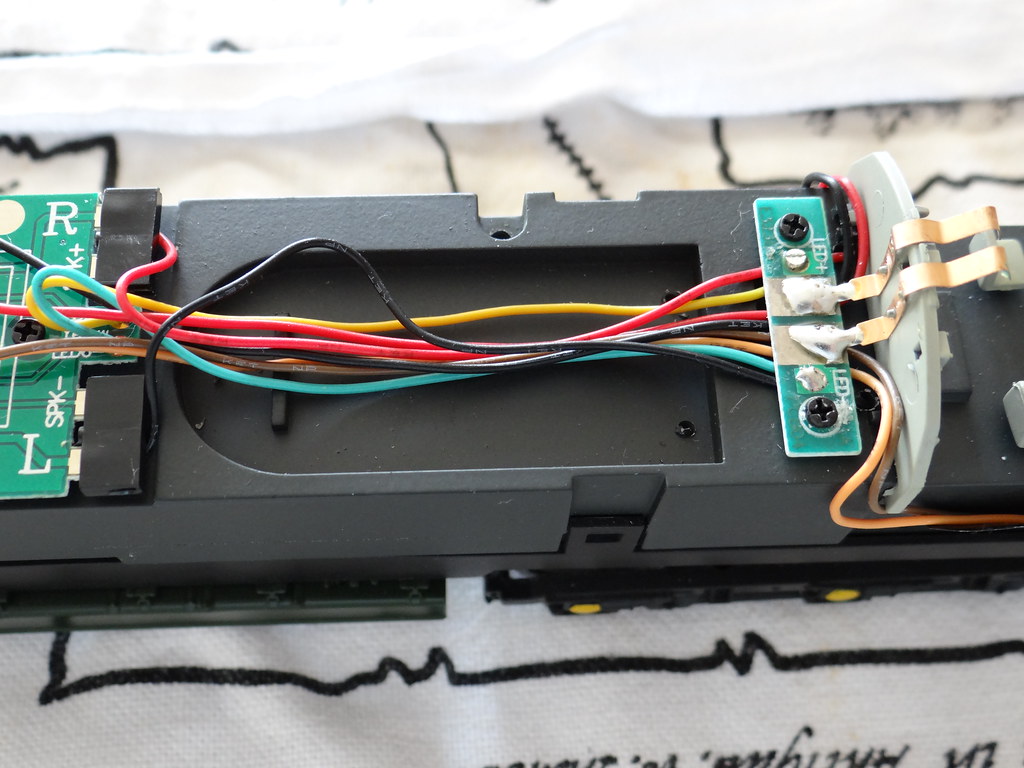

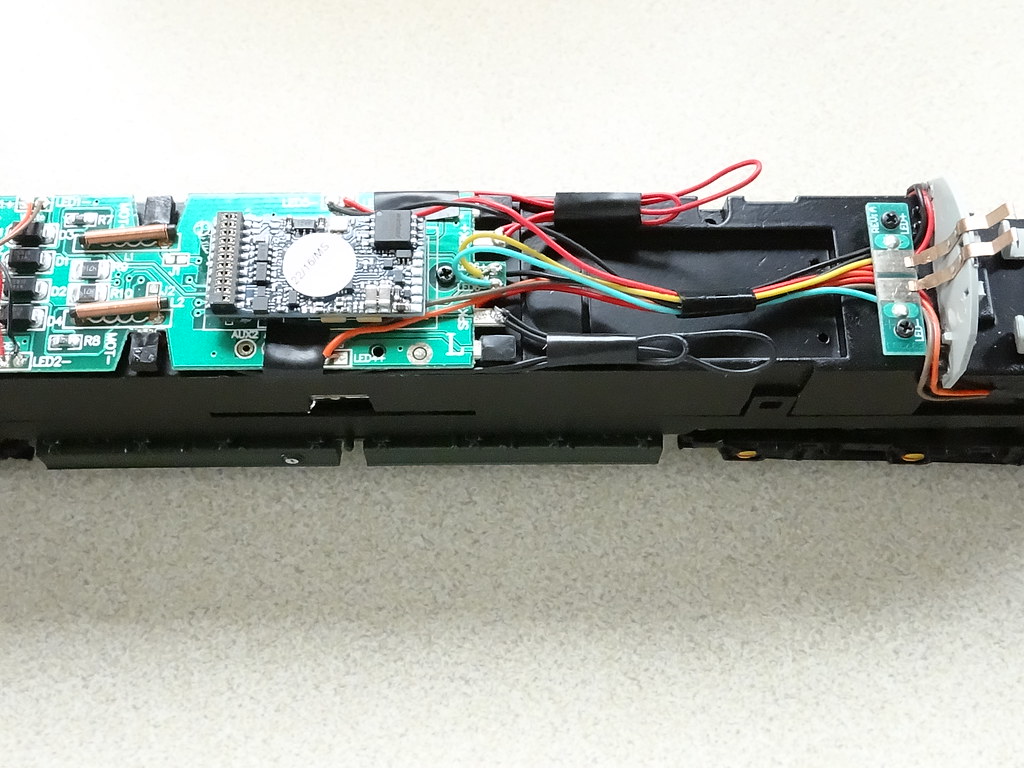

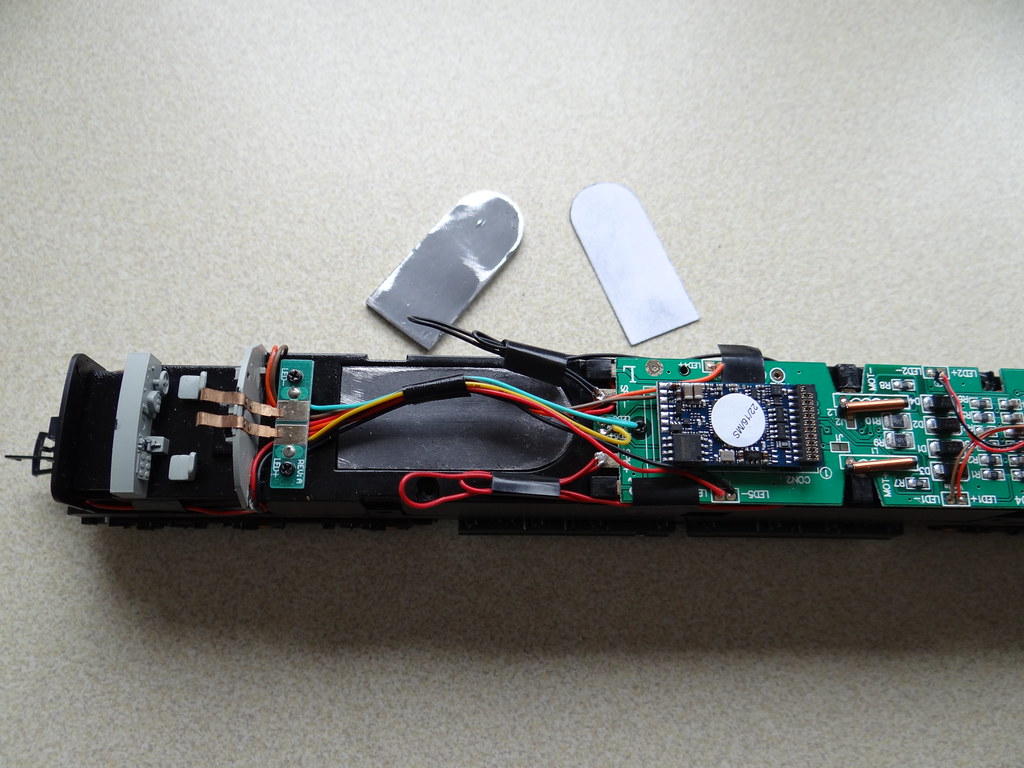

All the wires reattached and the PCBs screwed back in

place

It is then ‘simply’ a case of reattaching all the leads and

screwing the PCBs back in place. The Green Howards did not come with any black

plastic connectors for the sound ‘socket’ on the PCB so the leads from the

speakers were attached by solder, keeping the two black leads to one tab and the

two red leads to the other tab. Any surplus speaker wire was carefully bundled

and held together with black tape.

Adding some extra ballast

As purchased, ‘The Green Howards’ weighed just under 600g.

After butchering the ballast weight in the fuel tanks the weight dropped to

around 530g. Is this significant – I don’t know. However there is the void on

top of the chassis provided by Bachmann for their speaker. I made a card template

to drop into this space which I used to cut a couple of pieces of lead from 2mm

sheet, holding them in place with double sided tape. The net result was to

raise the weight of ‘The Green Howards’ up to 570g. There is room to add lots

more lead. However my two pieces fitted tidily under the existing wiring and I

decided to stop there.

What do I think of the resulting sound? I am well pleased. I

did try the engine with the LokSound speaker before making any alterations, it

was thin and tinny. The sound from the two bass speakers seems to me to be in a

higher league and has certainly impressed a few visitors.

Bachmann 'The Green Howards' with digital sound running

on Analogue DC

As an aside, when ‘The Green Howards’ first arrived on the

layout the cab lights did not work at one end of the locomotive. I eventually

traced the problem to the connection between the copper strips and the PCB (the

ones that came factory soldered on 'The Duke of Wellington's Regiment'). The

latter PCB seemed to be coated with varnish or possibly soldering flux. After a

light clean with some emery paper the cab lighting was restored. Now after

installing the LokSound chip the cab lights were again extinguished (on

analogue DC). This time it was not an electrical problem but a case of changing

one of the chips analogue default settings with my SPROG.

Comments