No. 162 Black Friday Black Five

I have lost count of how many Black Fridays there are in November but I used each Friday (and some of the other days) to stock up on more of Hornby’s Super Detail Black Fives.

One of Hornby’s newer models with Combined Top Feed, 45190 aka R2904

I bought 45190 my first super detail Black Five back in 2011. I was underwhelmed by how lightweight the engine was and how little it could haul. As a result it spent the next few years resting at the end of the engine shed headshunt. Most recently I have been following Dan’s Stranraer Harbour thread on RMweb and have been inspired to revisit my Black Five. https://www.rmweb.co.uk/community/index.php?/topic/140736-now-with-videos-stranraer-%E2%80%98themed%E2%80%99-loft-layout-1959-64/

Some older models, 44781 and 44871 aka Hornby R2686A&B

I don’t think that I had ever looked inside the engine but the front end of the boiler and smoke box is empty. Despite what it doesn’t say on the box, all the super detail models that I have seen are DC ready. The early models have an eight pin socket in the front of the boiler whilst the later models have had the socket moved to the tender. To make room for the digital chip the front of the boiler and smokebox are empty—even for the models where the socket is in the tender. Of course running a 12 volt DC analogue layout I can take advantage of the space reserved for the chip and add some lead ballast.

A newer model, 44694 aka Hornby R3323

Out of the box the Hornby Black Five weighs between 240 and 255gm. Hornby have produced a large number of models each subtly different. Having the digital socket in the engine or in the tender will account for part of this difference in weight but I think there must be other factors in play which I have not been able to identify. (Different recipe for the metal in the chassis?) Sadly I didn’t keep detailed records of the start weights of all the different models but I thought 44694 was a 240gm engine whilst 44908 was a 255gm model.

44694 at 240gm

44908 at 255gm

My layout is rather up and down and experimenting showed that I needed an engine weight approaching 295gm. Again after more experimentation I found it possible to add small rectangles of lead to the smoke box totalling around 40gm. To get even closer to my target value I also added lead beneath the digital socket and in one case inside the top of the boiler.

c10gm lead beneath the socket covered with insulating tape

c15gm lead along the top of the boiler – clipped into the top feed and held by insulating tape

I cut pieces of lead from ‘1/8th inch sheet’ as used by roofers for flashing. For slotting into the smoke box the pieces must be less than 23mm length. I used a selection of widths starting at 18mm maximum, through 17,16, 14.5 down to 13 or 12mm. Depending on the actual thickness of the lead sheets you might be able to go down to less than 10mm. The largest sheets have to be slid in first at an angle to avoid the chimney spigot. The smaller sheets can then follow added horizontally. I have deliberately left the sheets loose so that they could be removed at a later date.

Does all this weight in the front of the boiler make the engine front heavy? Yes, but...... The engine to tender connection for both the old and new models, probably more by accident than design, transfers the weight of the tender to the engine and helps to hold the back of the engine down.

For the newer models with the digital chip in the tender there is even more space in the engine for lead!

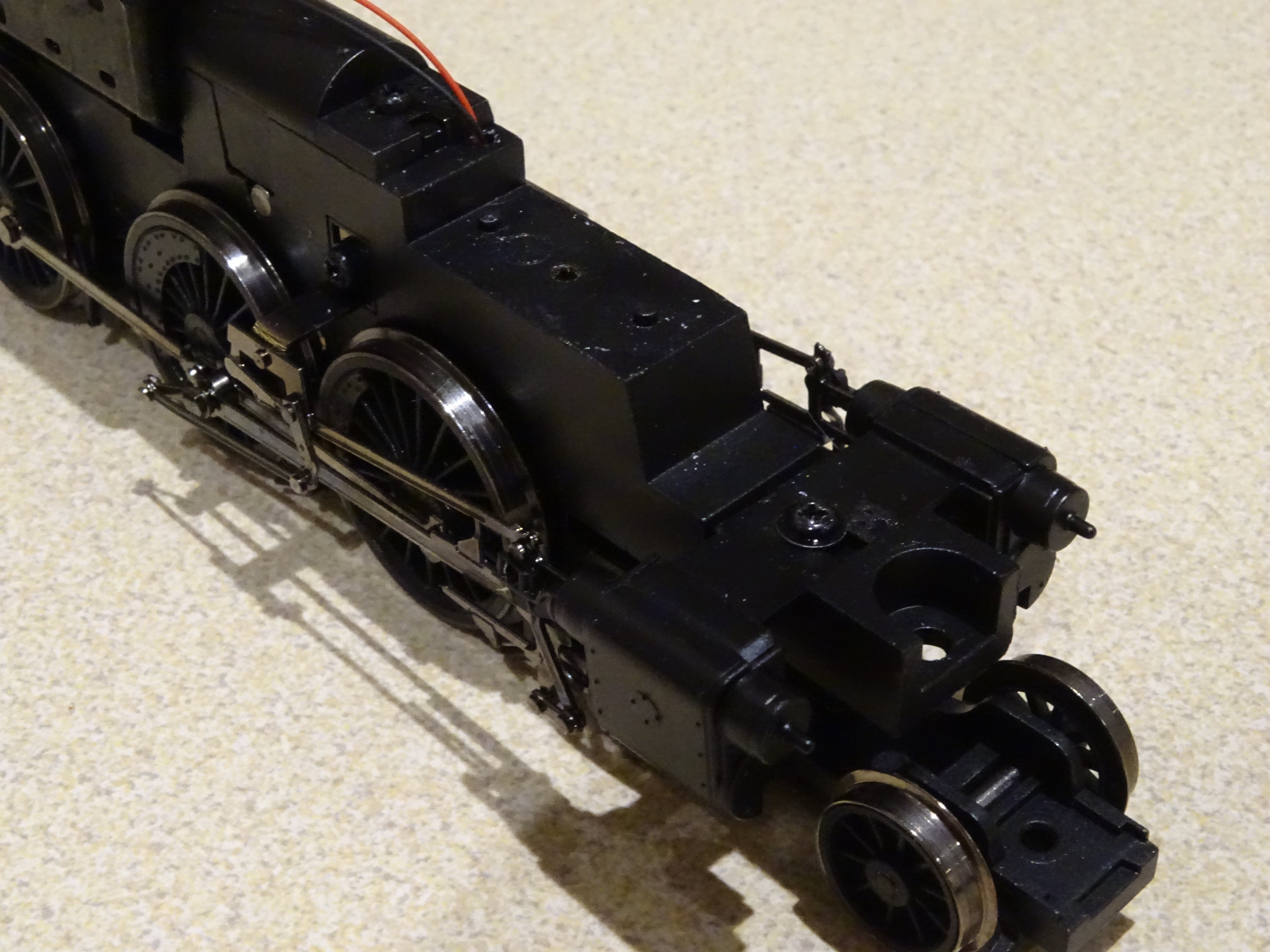

45190 aka Hornby R2904 a newer model with the socket in the tender

c20gm lead in place of the digital socket – held in place by double sided tape.

As noted above Hornby have produced a range of models and I have attempted to catalogue those that I might have seen in service in the late 1950s and 1960s omitting any weathered models. (I doubt this list is complete as I keep spotting ‘new’ Hornby models.)

Hornby BR era Super Detail Black Fives

I have listed the models by running number showing also the Shed Code printed on the model. I have then listed the different liveries that were carried. I suspect that the plain black livery was only applied in the middle to late 1960s just before the end of steam. Similarly some models have the top lamp iron moved down and to the right. This again was an end of steam feature associated with running beneath the overhead wires dating from the early 1960s.

Lamp Iron centre top 44668 aka Hornby R2322

Lamp Iron right hand down a bit 44781 aka Hornby R2686A

The Black Fives were introduced by Sir William Stanier before the Second World War and were completed in the 1950s under the direction of HG Ivatt. The engines were built by both the LMS and BR (LMR), and outside contractors, with the result that there were numerous differences between class members. Hornby have modelled three types of boiler, distinguishable by the position of the top feed: forwards, rear or combined.

Top Feeds, rear (top) and forward (bottom)

There was also a difference in the wheel spacing on some engines between the centre and rear drivers – which might have been due to a difference in firebox size. Hornby have cunningly engineered a plastic insert slotted into the mazac chassis to carry the rear wheel bearings which can be turned through 180 degrees to provide either the required long or short wheel spacing. I have identified three different tender types: fully riveted, part riveted where the sides have been smoothed, and fully welded where both the back and sides are smooth. In addition tenders come with an Early Emblem, or a Late Crest.

Fully Riveted tender

Part Riveted tender

Fully Welded tender

During their short lifetime it is quite likely that whilst visiting ‘the works’ engines might receive tenders and boilers different from the ones originally fitted. I have carried out some random checks of pictures on Flickr and to date have not come across any conflicts with Hornby’s models.

When you have added all the lead possible, the engine may still underperform. Remember it is Hornby and you do need to check and adjust the phosphor bronze pickups or wipers on the tender wheels. Frequently these springy bits of metal stick out so far that it is reminiscent of driving an old car with the handbrake on. (If it is an analogue layout and the track is clean you probably don’t need the tender pickups anyway and they can be flattened.)

Tender bottom plate

Further sources of unwanted friction are the axle slots in the plastic keeper (bottom plate) for the tender. I had to run a drill bit through the slots and shave some of the plastic from around the openings for the socket and the rear coupling. I first noticed the issue with one of the later models and wondered whether it might be due to wear on the factory moulding tools resulting in an oversize moulding with reduced clearances.

On the whole I have been very impressed with the Super Detail Black Fives. The cab wind deflectors are particularly delicate and don’t cope very well with travel by Royal Mail but that is common to a lot of Hornby’s models.

The Christmas Quiz model 44694 aka Hornby R3323

The only real problem model that I have come across has been 44694. When it first arrived I thought of posting its picture for a Christmas Quiz – spot what was wrong. Even before it arrived I had discovered that the large steam dome was likely to be back to front. I had not factored in that the cab wind deflectors would be upside down. For good measure I also had to reattach the whistle that had been broken off in transit. Fixing the dome was easier than I imagined. I made a pilot hole by rotating a tiny drill bit by hand into the plastic spigot inside the boiler. I then reamed the hole out with a Philips screwdriver until the dome popped off. If you are careful there will still be enough of the original plastic spigot to pop it back in place, after rotating through 180 degrees. The cab wind shields will have to stay upside down – who is going to notice?

Lastly two of my favourite models; 45156 Ayrshire Yeomanry and 45157 Glasgow Highlander. The latter was a real Scottish engine shedded in Glasgow for most of its life. The former spent the final years of its life in the Manchester area.

45157 Glasgow Highlander aka Hornby R2449

Hornby correctly depict 45156 with its British Railways combined dome and top feed – not to be confused with the currently preserved engine, originally numbered 45337, which now carries the Ayrshire Yeomanry name (and number) but which has a separate dome and top feed.

45156 Ayrshire Yeomanry aka Hornby R2555

Addendum 03.01.21

Since publishing this Post I have gleaned further information on the different models produced by Hornby.

It had escaped my notice that some models have fluted coupling rods and some have plain rods. Also some engines have an addition to the left hand cross head which I am told is left over from when early engines were fitted with vacuum pumps.

Modified Cross Head with connection for vacuum pump.

I have also updated ‘The Table’ above with some details of the sound fitted engines.

The first two sound models came with LokSound v3.5 chips and will run and play sound on analogue. The newest sound model is TTS fitted and presumably will run on analogue but only play sounds on digital.

Another Quality Control issue

One of my latest purchases did not run well – the wheels beneath the cab seeming to jump around. On closer inspection I could see that the two rear sand pipes had been fitted on the wrong sides. Instead of the pipes being recessed behind the coupling rods they were stuck outwards pressing against the rods. These were factory fitted pipes and I was unsure that would be able to rectify without cutting through the pipes. I used a very sharp blade and started to cut the glue around the junction between the pipe and the sand box. The glue cut quite easily and after not a lot of effort the pipe (with its spigot) could be prised free. I don’t know what glue Hornby had used but it did not seem to have fused the plastic parts together. Perhaps the sand pipes are nylon which would not fuse to the plastic sandbox?

45458 - yet another Scottish Engine

One more picture of a Scottish engine! Hornby have 45458 with a Scottish Region blue background to its smokebox number and shed plates. The 66A shed number is Glasgow Polmadie from where the engine was withdrawn. It seems a strange choice of shed plate as a web search suggests that 45458 was a 63A Perth based engine for most of its life and may only have been at Polmadie for a few months before withdrawal.

Comments